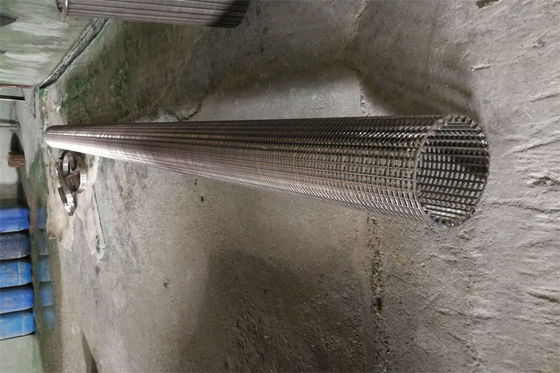

Spiral Xinlu V Wire Sand Control Screen With Continuous Slot Opening

Products Quickly Details:

1. Product Name: Johnson V Wire-Wound Strainer Sand Control Screen Pipe, v wire water well screen, wire wrapped screen pipe, Johnson specialty screen, spiral screen tube, strainer pipe, rod based continuous slot wedge wire screen, drilling well screen, reversed rolled slot well screens, screen cylinders, continuous-slot well screen, Well screen, water filter, filtration element

2. Material : Low carton, mild steel wire, iron wire, low carton galvanized steel (LCG), stainless steel (201, 205, 304, 316, 316L, 321 etc.), Duplex stainless steel

3. Diameter: DN 20-1000mm (1-40inch)

4. Slot size: 0.05mm,0.08mm,0.1mm,0.15mm,0.20mm,0.25mm,0.30mm,0.50mm,0.75mm,1.0mm... 6.00mm also achieved upon request.

5. Length: 500mm,1000mm,1500mm,2000mm,..... ,6000mm.

6. End connection: Plain beveled ends for butt welding (welded ring)or threaded male &female coupling (API STC, PT NPT, BSP, G, ).(spiral), Flange, Closed up

7. Surface Electrolytic polishing, Pickling and polishing or Galvanized

The production of these Xinlu V Wire Sand Control Screen is by now consolidated, actually it has been produced since 2006 and it was preceded by "Anti-sand" screen, which was manufactured with an inside simple screen.

Thanks to the experience and to the advanced technological machineries, nowadays it is possible to manufacture water screen with diameters from 25 to 1500 mm and with lengths up to 6 metres.

It is the Xinlu V Wire Sand Control Screen that through the past years has been employed more and more, just for its excellent technical features.

The water screen, manufactured with a trapezoidal / triangular section of the spiral wrapped wire on loading rods according to the generators of a cylinder, can have slots from 0,10 mm onwards, so as to satisfy every request and every projecting need or of installation.

As already known, spiral screen for water well, like Johnson Sand Control Screen, have, with equal diameter and slot, bigger opening surfaces than the ones of other kinds of screens (bridge or simple slot screen).

The higher percentage of opened area enlarges the profit of water. In Xinlu V Wire Sand Control Screen, the wide opened area simplifies enormously (in comparison with other screens) the washing of the well when, for instance, it is necessary to eliminate the mud panel.

In favour of the spiral Xinlu V Wire Sand Control screens there is the chance to have smaller slots than the ones of other kinds of screen.

This is a great advantage when you have to filter waters in slimy soils where it is therefore necessary that the drain is of a very low grain size and that, at the same time, it cannot pass through the screen for water well itself.

Moreover, in rotation perched wells by inverted circulation, if the hollow space hole/casing is very small and such not to allow the forming of artificial drains, it is better to employ these Johnson Sand Control Screen with slots of 0,10 mm.

Packaging & Delivery: V Wire Sand Control screens

With plastic film or buble package with weave bag, then packed in wooden boxes or container

Plastic bubble bag packaging

Transparent plastic bag inside, woven bag outside

Wooden box

Pallet

According to your requirment.

V Wire Sand Control screens Data reference table:

sizes

(inch) |

OD

(mm) |

slot

(mm) |

Length

(m) |

Tenslile

strength |

collapse

Strength |

wrap wire

vee-shaped wire

(Width x height:mm)

|

support rod

Round wire (mm) |

| 3-1/2 |

88.9 |

1 |

2.9 |

>22 |

10.2 |

2.3 x 3.5 |

3.0MMx22 |

| 4-1/2 |

114.3 |

1 |

2.9 |

>28 |

11.5 |

2.3 x 3.5 |

3.0MM×22 |

| 6-5/8 |

168.3 |

0.75 |

5.8 |

>40 |

12.8 |

2.3 x 3.5 |

3.8MM×32 |

| 6-5/8 |

168.3 |

1 |

5.8 |

>33 |

12.8 |

2.3 x 3.5 |

3.8MM×32 |

| 6-5/8 |

168.3 |

0.63 |

5.8 |

>83 |

45 |

3.0 x 6.0 |

5.OMM×32 |

| 8-5/8 |

219.1 |

1 |

5.8 |

>34 |

21.9 |

2.3 x 3.5 |

3.8MMx48 |

| 8-5/8 |

219.1 |

1 |

5.8 |

>50 |

38.2 |

3.0 x 4.6 |

4.0MMx48 |

| 8-5/8 |

219.1 |

1 |

5.8 |

>60 |

46 |

3.05 x 6.35 |

5.0MMx48 |

| 10-3/4 |

273.1 |

0.75 |

5.8 |

>50 |

9 |

2.5 x 4 .0 |

3.8MM×55 |

| 10-3/4 |

273.1 |

1 |

5.8 |

>60 |

39.5 |

3.0 x 4.6 |

4.5MMx55 |

| 10-3/4 |

273.1 |

1 |

5.8 |

>100 |

48 |

3.2 x 6.0 |

5.0MM×55 |

| 12-3/4 |

323.9 |

1 |

5.8 |

>120 |

37.2 |

3.0 x 6.0 |

4.0MMx56 |

| 14 |

355.6 |

1 |

2.9 |

>80 |

37.8 |

3.0 x 5.0 |

4.0MMx59 |

| 16 |

426 |

1 |

2.9 |

>80 |

37.5 |

3.0 x 5.0 |

4.OMM×64 |

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.50 |

1.50 |

2.30 |

2.30 |

1.80 |

3.00 |

3.70 |

3.30 |

| HEIGHT(mm) |

2.20 |

2.50 |

2.70 |

3.60 |

4.30 |

4.70 |

5.60 |

6.30 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

2.30 |

2.30 |

3.00 |

3.70 |

3.30 |

Ø2.5--Ø5mm |

| HEIGHT(mm) |

2.70 |

3.60 |

4.70 |

5.60 |

6.30 |

---- |

FAQ

The Important Question: How Many Meters of the well deep can be used in?

A: Common screen pipes can be used in wells with a depth of 200-300 meters.

Large wire can also be customized for 650m deep well.

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

---------------------------------------------------------------------------------------------------------------

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!