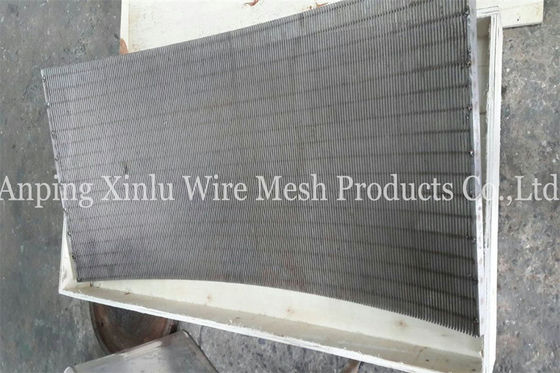

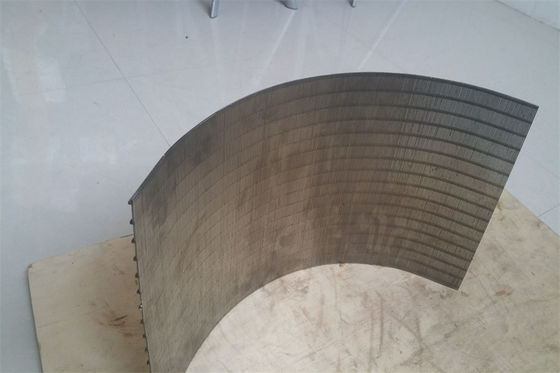

45°-120° Wedge Wire Johnson DSM Screen Sieve Bend, Arc Screen Plate

Quickly Details:45°-120° Wedge Wire Johnson DSM Screen Sieve Bend, Arc Screen Plate

45° DSM Screen – Commonly used for thickening and screening.

120° DSM Screen – Pulp thickening, recovery, and separation of fibers.

800 mm arc length – Media recovery. Use at height limit.

1600 mm arc length – Made for maximum drainage.

1200 mm arc length – Maximum drainage, but the height does not allow 1600 mm.

We can customize suitable products according to the actual use.

High capacity

Not easy to block

Wear resistance

Large opening rate

Simple installation

Low maintenance costs

The arc angle of 45°, 60°, and 90° are often adopted for self flow DSM screen, used in coal preparation plant and concentrator.

The pressure type DSM screen, which usually adopts the arc of 180° and 270°, is used in the grading operation of the grinding process in the cement industry.

Because of the great discharge capacity of the sieve bend screen, many coal preparation plants often use it for pre-dewatering before the dewatering screen, and the gap between the screens is generally 3-6 times larger than that of the dewatering screen in the next process, but the maximum slot should not exceed 3 mm.

The width of the sieve bend screen shall be 150-200mm smaller than that of the dewatering screen in the next process. Arc screen can also be used in series as required.

We have accumulated rich production experience and can give professional suggestions according to the specific use of customers.

Advantages of 45°-120° Wedge Wire Johnson DSM Screen Sieve Bend, Arc Screen Plate

– Wedge Wire

Minimum wire diameter: 0.5mm (width) x 1.2mm(height)

The opening area is determined by the width of the wedge wire and the gap size, when the slot size is determined, only the finer wedge wire can be used to improve the opening rate.

We are one of the few manufacturers in China with a diameter of 0.5mm, it can maximize the opening area.

High capacity.

– Large transverse strength

If there is not enough transverse strength, the sieve bend (DSM) screen will bend to the side, and the precision of the gap will change.

– High vertical strength

More important than the transverse strength, the important factors affecting product performance.

– Wear and corrosion resistance

We choose the best raw materials and special surface treatment technology, which can improve the wear resistance and corrosion resistance of the products, with long service life.

– Custom wedge wire angle (reasonable design of water cutting)

A wedge wire with a skew angle has better screening ability in use.

We can customize the angle: 3°- 15°.

The size of the angle depends on the width of the wedge wire and the size of the gap, our technicians will provide the most professional advice.

– Firm structure

Perfect welding process, welding every intersection, very solid structure.

– Easy to install, easy to replace, no maintenance required

– Save energy, space, and noise

The application environment of wedge wire sieve bend screen with different angles is different.

45°SIEVE BEND SCREEN: Thickening and screening

120°SIEVE BEND SCREEN: Widely used in paper mills, thickened pulp, recycled fiber.

Before purchase, it is necessary to confirm with the supplier: material, wedge wire size, gap size, length and width, angle, and other basic specification information.

We are the largest wedge wire screen manufacturer in northern China, with three complete production lines, which can provide customized sieve bend screen services for customers all over the world.

45°-120° Wedge Wire Johnson DSM Screen Sieve Bend, Arc Screen Plate Wire Specification:

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.50 |

1.50 |

2.30 |

2.30 |

1.80 |

3.00 |

3.70 |

3.30 |

| HEIGHT(mm) |

2.20 |

2.50 |

2.70 |

3.60 |

4.30 |

4.70 |

5.60 |

6.30 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

2.30 |

2.30 |

3.00 |

3.70 |

3.30 |

Ø2.5--Ø5mm |

| HEIGHT(mm) |

2.70 |

3.60 |

4.70 |

5.60 |

6.30 |

---- |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!