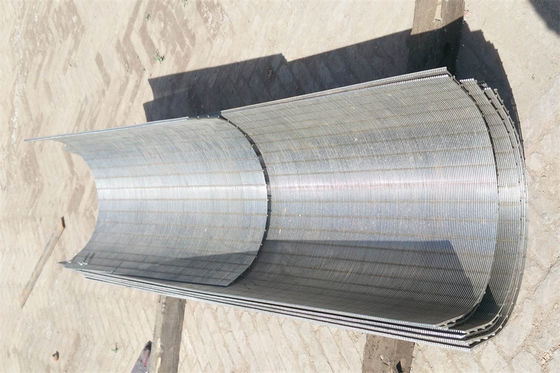

Wedge Wire profile v wire arc screen plate for waste water treatment

Category: Sieve Bend Screen

Material: stainless steel 304,304L,316,316L,321,430 or as per your request.

Properties: sieve bend screen

Application: water-treatment,beer brewing,water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant, refining & petrochemical

Details of Wedge Wire profile v wire arc screen plate for waste water treatment equipment

Wedge Wire profile v wire arc screen plate also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens, can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, waste water cleanup, surface water intakes, corn wet milling, coal preparation, and gold recovery.

Wedge Wire profile v wire arc screen plate can be used in a variety of applications ranging from classifying to recovering usable products that would end up in sewer lines to capturing solids from effluents. A continuous slot screen sieve bend gives you a great amount of open area, is significantly more affordable and requires less maintenance than vibrating or rotary drum options.

Application of Wedge Wire profile v wire arc screen plate for waste water treatment

They are used in industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Features of Wedge Wire profile v wire arc screen plate for waste water treatment

Compact construction, heat resistant, rust-resistant, good mechanism performance, long working life, wear-resistant;

Well-proportioned screen aperture, not prone to jam, increase quality and efficiency of refined powder;

Proper construction, saving time and strength during installation and replacement, i.e. reducing time for installation, examination and maintenance, decreasing labor strength.

Customizable of Wedge Wire profile v wire arc screen plate for waste water treatment

According to your requirements, we can process and manufacture various shapes of sieve plates.

Wedge Wire Sieve Bend Panelconsists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Slot: form 0.1mm, tolerances: ± 0.05mm.

Maximum size: 3000mm x 4000mm.

Material: Low Carbon, Low Carbon Galvanized steel (LCG), Stainless Steel ( 304, 304L, 316, 316L, etc).

Various applications including:

- Food processing

- Pulp and paper processing

- Rubbish removal from water

- Water intakes

- Coal preparation

- Gold recovery

Wedge Wire Specification:

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.50 |

1.50 |

2.30 |

2.30 |

1.80 |

3.00 |

3.70 |

3.30 |

| HEIGHT(mm) |

2.20 |

2.50 |

2.70 |

3.60 |

4.30 |

4.70 |

5.60 |

6.30 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

2.30 |

2.30 |

3.00 |

3.70 |

3.30 |

Ø2.5--Ø5mm |

| HEIGHT(mm) |

2.70 |

3.60 |

4.70 |

5.60 |

6.30 |

---- |

---------------------------------------------------------------------------------------------------------------

Our factory Xinlu Wire Mesh product co., Ltd located in Anping country, Hebei Province, China.

Our mainly products are: stainless steel vee sharped wire / wrap wire, johnson type screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainless steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod based continuous slot screens, header and hub laterals & hub radial laterals etc.

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!