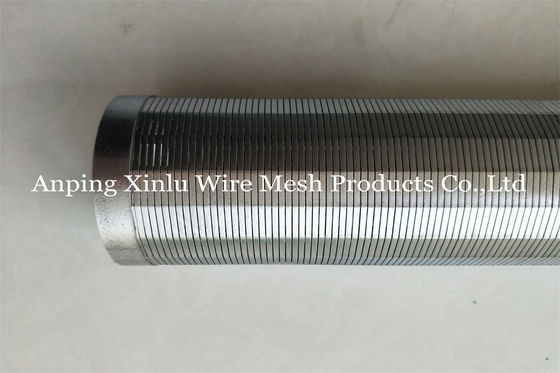

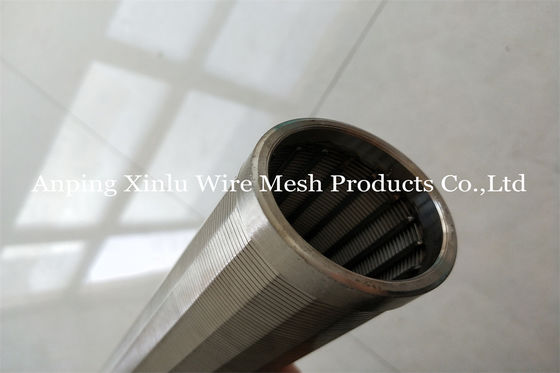

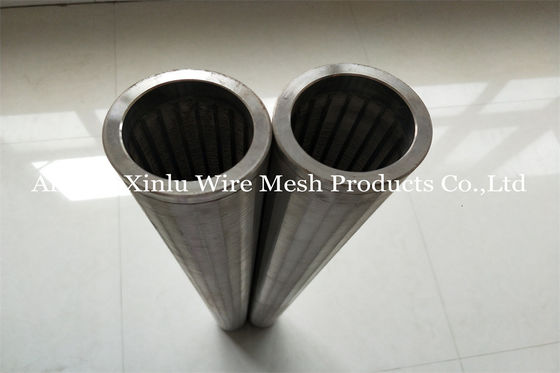

Pump Filter 75mm Johnson Vee Wire Wrapped Continuous Slotted Screen Pipe

water well screen, perfect roundness screen tube, profile wire screen pipe, wedge wire screen, wire wrapped screen, screen tube, screen pipe, sand control well screen, oil well screen, v wire slot screen, rod based continuous slot screen, wire wound stainless steel screen pipe, johnson well screens, Continuous slot well screen, wire screen, Johnson screen, Johnson V Wire Stainless Steel Well Screens

continuous slot well screen,water well screen

A well screen is a filtering device that serves as the intake portion of wells constructed in unconsolidated or semi-consolidated aquifers. The screen permits water to enter the well from the saturated aquifer, prevents sediment from entering the well, and serves structurally to support the aquifer material. The importance of a proper well screen cannot be overemphasized when considering the efficiency of a well and the log-term cost to its owner.

Well screens are manufactured from a variety of materials and range from crude handmade contrivances to highly efficient and long-life models made on machines. The value of a screen depends on how effectively it contributes to the success of a well. Important screen criteria and functions include:

characteristic

1. large percentage of open area

2. non clogging slots

3. resistant to corrosion

4. sufficient column and collapse strength Functions:

1. easily developed

2. minimal incrusting tendency

3. low head loss through the screen

4. control sand pumping in all types of aquifers

Continuous-Slot Screen

| Product |

Continuous slot well screen, wire screen, Johnson screen |

| Slot Size(mm) |

0.10, 0.15, 0.2, 0.25, 0.30-3, also achieved upon customer request. |

| Material |

Low Carbon ,Low Carbon Galvanized steel (LCG), Stainless Steel( 304,etc.) |

| Lengths |

up to 6 meters |

| Diameter |

89 mm to 1200 mm |

| End Connection |

Plain beveled ends, welding rings, flanges or threaded ( Thread male/female coupling ) . |

| The data for reference only, we can design it as the client’s request. |

Continuous-Slot Well Screen is made by a v or wedge winding cold-rolled wire around an internal array of longitudinal support rods. The world advanced all-welded technology is used with each intersecting point of these wire fusion welded, which creates the robust construction and excellent mechanical performance. The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water or oil entry your well freely in ample quantities, while at the same time keeps the majority of sand and gravel out of the well. All slots should be clean and free of burrs and cuttings and can be changed according to clients’ need.

Application: For water, oil and gas wells, mainly water well industry. Can be used for water treating equipment, sea water transforms into industrial water equipment and life use water desalination treatment, running water treatment, water softening treatment. And the petroleum product terminal filters and chemical acid, alkali liquid filters, ethyl alcohol and the organic solution recycling filters.

Johnson V Wire Well Pump Filter Screen Specification:

| Screen Size |

Inside Diameter |

Outside Diameter |

OD of Female Threaded End |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

| 2 |

51 |

2 |

51 |

2 5/8 |

67 |

2 3/4 |

70 |

| 3 |

76 |

3 |

76 |

3 5/8 |

92 |

3 3/4 |

95 |

| 4 |

102 |

4 |

102 |

4 5/8 |

117 |

4 3/4 |

121 |

| 5 |

127 |

5 |

127 |

5 5/8 |

143 |

5 3/4 |

146 |

| 6 |

152 |

6 |

152 |

6 5/8 |

168 |

7 |

178 |

| 8 |

203 |

8 |

203 |

8 5/8 |

219 |

9 1/4 |

235 |

| 10 |

254 |

10 |

254 |

10 3/4 |

273 |

11 3/8 |

289 |

| 12 |

305 |

12 |

305 |

12 3/4 |

324 |

13 3/8 |

340 |

| 14 |

356 |

13 1/8 |

333 |

14 |

356 |

- |

- |

| 16 |

406 |

15 |

381 |

16 |

406 |

- |

- |

| 20 |

508 |

18 3/4 |

476 |

20 |

508 |

- |

-

|

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

---------------------------------------------------------------------------------------------------------------

Our mainly products are: stainless steel vee sharped wire / wrap wire, johnson type screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainless steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod based continuous slot screens, header and hub laterals & hub radial laterals etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!