8 5 / 8 " Water Well Continuous Slot Screen V Wedge Shaped Metal Material

water well screen, perfect roundness screen tube, profile wire screen pipe, wedge wire screen, wire wrapped screen, screen tube, screen pipe, sand control well screen, oil well screen, v wire slot screen, rod based continuous slot screen, wire wound stainless steel screen pipe, johnson well screens, Continuous slot well screen, wire screen, Johnson screen, Johnson V Wire Stainless Steel Well Screens

Description of johnson type Water Well Continuous Slot Screen

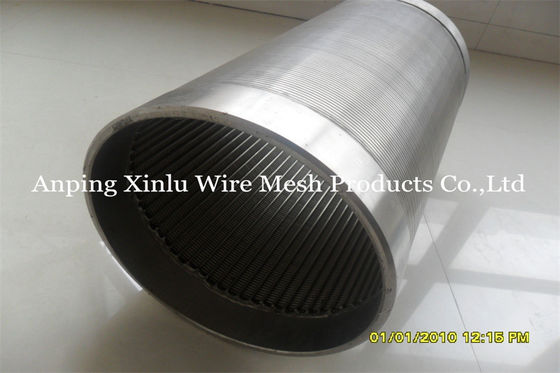

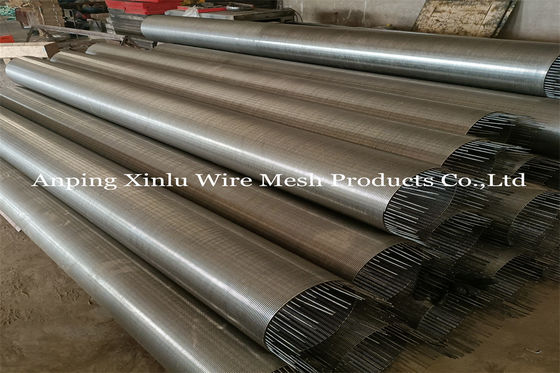

water well screen/ johnson screen filter mesh with high quality are manufactured by a or the v wedge shaped wire around an internal array of longitudinal support rods. With the advanced all-weld technology, the each interesting point makes construction robust and mechanical performance excellent. The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening and larger filtering area, hence the screen allows water(oil) to enter your well freely and smoothly in ample quantities, while keeps sand and gravel out of the well. The slots can be changed according to different strata.

characteristic: 8 5 / 8 " Water Well Continuous Slot Screen V Wedge Shaped Metal Material

1. large percentage of open area

2. non clogging slots

3. resistant to corrosion

4. sufficient column and collapse strength Functions:

1. easily developed

2. minimal incrusting tendency

3. low head loss through the screen

4. control sand pumping in all types of aquifers

Continuous-Slot Screen

The continuous-slot screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry. It is made by winding rolled wire, triangular in cross section, around a circular array of longitudinal rods. The wire is attached to the rods by welding. Welded screens are commonly fabricated from stainless steel.

The continuous-slot screen is widely used throughout the world for water,oil,and gas wells,and is the dominant screen type used in the water well industry. Continuous-slot screen is made by winding cold-rolled wire,approximately trianngular in cross section,around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights. Slot opening for continuous screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burns and cuttings.

Water Well Continuous Slot Screen V Wedge Shaped Metal Material Specification:

|

sizes

(inch)

|

OD

(mm)

|

slot

(mm)

|

Length

(m)

|

Tenslile

strength

|

collapse

Strength

|

wrap wire

vee-shaped wire

(Width x height:mm)

|

support rod

Round wire (mm)

|

|

3-1/2

|

88.9

|

1

|

2.9

|

>22

|

10.2

|

2.3 x 3.5

|

3.0MMx22

|

|

4-1/2

|

114.3

|

1

|

2.9

|

>28

|

11.5

|

2.3 x 3.5

|

3.0MM×22

|

|

6-5/8

|

168.3

|

0.75

|

5.8

|

>40

|

12.8

|

2.3 x 3.5

|

3.8MM×32

|

|

6-5/8

|

168.3

|

1

|

5.8

|

>33

|

12.8

|

2.3 x 3.5

|

3.8MM×32

|

|

6-5/8

|

168.3

|

0.63

|

5.8

|

>83

|

45

|

3.0 x 6.0

|

5.OMM×32

|

|

8-5/8

|

219.1

|

1

|

5.8

|

>34

|

21.9

|

2.3 x 3.5

|

3.8MMx48

|

|

8-5/8

|

219.1

|

1

|

5.8

|

>50

|

38.2

|

3.0 x 4.6

|

4.0MMx48

|

|

8-5/8

|

219.1

|

1

|

5.8

|

>60

|

46

|

3.05 x 6.35

|

5.0MMx48

|

|

10-3/4

|

273.1

|

0.75

|

5.8

|

>50

|

9

|

2.5 x 4 .0

|

3.8MM×55

|

|

10-3/4

|

273.1

|

1

|

5.8

|

>60

|

39.5

|

3.0 x 4.6

|

4.5MMx55

|

|

10-3/4

|

273.1

|

1

|

5.8

|

>100

|

48

|

3.2 x 6.0

|

5.0MM×55

|

|

12-3/4

|

323.9

|

1

|

5.8

|

>120

|

37.2

|

3.0 x 6.0

|

4.0MMx56

|

|

14

|

355.6

|

1

|

2.9

|

>80

|

37.8

|

3.0 x 5.0

|

4.0MMx59

|

|

16

|

426

|

1

|

2.9

|

>80

|

37.5

|

3.0 x 5.0

|

4.OMM×64

|

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

---------------------------------------------------------------------------------------------------------------

Our mainly products are: stainless steel vee sharped wire / wrap wire, johnson type screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainless steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod based continuous slot screens, header and hub laterals & hub radial laterals etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!