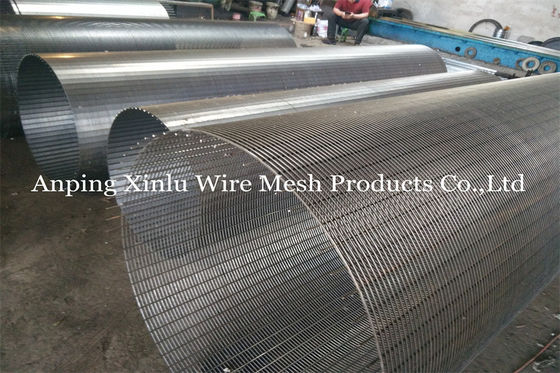

OD920mm x 1.0 x 3m Stainless Steel Johnson Type Wedge Wire Rotary Drum Screen

Cylinderical screen, Rotray Drum Screen, Filter Basket, Inverted Screen, Reverce Rolled Slot tube, Support screen, Commical basket, wedge wire strainer basket,stainless steel cylinder screen

Johnson Type Wedge Wire Rotary Drum Screen Flow Type:

Standard Construction(E.C.W): External circumferential wire and axial internal support rods

Axial wire construction: Vertical slots which allow beds of media to mover up and down without abrading the individual grains.

Internal Axial wire construction(I.A.W): creates long parallel slots. In vertical applications, media can move up and down with abrading. In horizontal rotating applications, flow moves across the wire edges for efficient dewatering.

Inverted wire constrction: External circumferential inverted wire and axial internal support rods

.

Johnson Type Wedge Wire Rotary Drum Screen Specification:

| Material |

Stainless steel |

| Grade |

304 |

| I.D |

920 MM |

| Slot Size |

1.0 mm |

| Components |

Reinforcing plate |

| Length |

3m, |

| Filter type |

From inside to outside |

| Wire size |

2.3x3.5 mm |

| Support rod |

3x4.6 mm |

| Wire shape |

V shape |

Johnson Type Wedge Wire Rotary Drum Screen Regular Specifications:

Material: stainless steel 302, 304, 316, 304L, 316L or low carbon galvanized

I.D.: 150 - 1000 MM

Slot: 0.1mm - 35mm

Discrepancy: + / - 0.05mm

Length: 300mm-3000mm

Specification of the wrap wire:1.5x2mm, 2x3 mm, 2.2 x 3.5 mm, 2.5x4mm, 3 x 4.6 mm and so on.

Specification of the rod: 1.8x2.5mm, 2x3 mm, 2.5x4mm, 3 x4.6 mm, 3x5 mm, and so on.

Filter Type: from inside to outside.

Other components : Flange, stiffener, lifting handle, and other type components by request.

Special specification can be made according to your need.

Industry:

Johnson Type Wedge Wire Rotary Drum Screen Pictures:

SIZES OF THE WIRE AND ROD

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.50 |

1.50 |

2.30 |

2.30 |

1.80 |

3.00 |

3.70 |

3.30 |

| HEIGHT(mm) |

2.20 |

2.50 |

2.70 |

3.60 |

4.30 |

4.70 |

5.60 |

6.30 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

2.30 |

2.30 |

3.00 |

3.70 |

3.30 |

Ø2.5--Ø5mm |

| HEIGHT(mm) |

2.70 |

3.60 |

4.70 |

5.60 |

6.30 |

---- |

Special specification can be made according to your need.

Benefits:

1. The application of the trapezoidal (wedge) wire forms a Vee-shaped opening between the screen and the gap between the screen plates. This design is more efficient than other forms of operation, ensuring smooth water filtration.

2. The trapezoidal (wedge) wire continuous winding forms a continuous high-density uniform gap on the circumferentially arranged support rods, ensuring the open area percentage and non-blocking of the screen, and avoiding the blockage caused by the high density accumulation of sediment.

3. The wire and all the longitudinal support rods are combined by electric welding connection, which is durable and has a longer working life.

4. The longitudinal support rod arrangement designed according to actual needs and the continuous gap form of the screen make the product have higher compression resistance.

Industry:

- Trommel screens with internal feed

- Systems with an internal rotor or screw

- Dewatering systems

- Automatic filters

- Fecal treatment

Pictures:

Package:

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

---------------------------------------------------------------------------------------------------------------

Our mainly products are: stainless steel vee sharped wire / wrap wire, johnson type screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainless steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod based continuous slot screens, header and hub laterals & hub radial laterals etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!