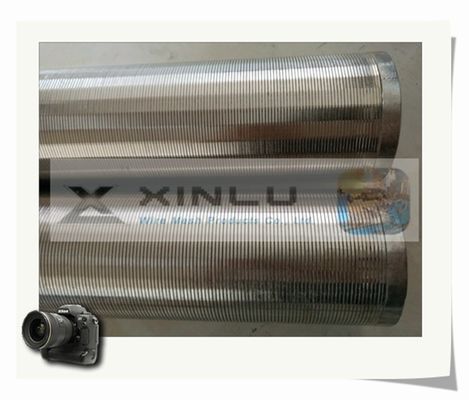

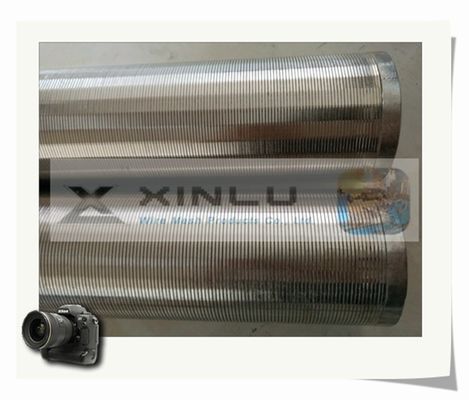

Wedge Wire Johnson Groundwater Screen Pipe, Dewatering Well Screen Tube

water well screen pipe, johnson well screeen, rod based wire wrapped screen, wedge wire screen, stainless steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod based continuous slot screens, header and hub laterals & hub radial laterals etc.

Johnson Screen Pipe mostly refers to V - Wire Water Well Screen.

Johnson screen Pipe is manufactured with V-shaped profile wire which is spirally wound around a cage of longitudinal support rods.

Each intersecting point of these wires is fusion welded. The pitch of winding gives different spacing between two adjacent turns of wire.

This spacing gives passage for water to enter. The entire process is completed on fully computerized machines.

Typical Specifications Of wedge wire johnson screen pipe:

Diameter Available:

1.5", 2", 3", 4", 6", 8", 10", 12", 14"

Slot (mm):

0.15,0.25, 0.50, 0.75,1.00,1.50,2.00,3.00

Lengths

6 Mts. & 3 Mts.

Material

Low Carbon Galvanized Steel ( LCG ) and Stainless Steel ( SS-304 )

Connection method:

beveled, circumferential welded, threaded connection

Features

1. High Open Area

More than 25% of open area allows water to seep through the dewatering screen at a reduce speed, while allowing for a lower flow resistance. The enhances the water removal rate, resulting in a more efficient water removal process.

2. Non-clogging Performance

Continuous slots widen inwardly from the screen surface to minimize the chance of sand clogging the slot opening,

3. Excellent Pressure Resistance

The wedge wire screen pipe is welded in a single from with no weld seams on the surface. Precise welding technology gives the screen its strength, making it ideal from high pressure applications

4. Great Sand Barrier

Precisely machined slots keep sand, silt and clay from entering the well, preventing abrasion.

5. Easy Installation

Compared to bridge slot screens or cement pipes, the wedge wire well screen in lightweight and easy to lay on the ground. It is also safe and convenient.

6. Material

The screen is available is galvanized, low-carbon steel, or stainless steel in grades 304 and 316, Premium materials do not retain sand and other impurities, ensuring a non-clogging performance.

Used:

Architecture & Construction

Food & Beverage Screens

Mineral & Aggregate Processing

OEM Screen Components

Pulp & Paper Screens

Refining & Petrochemical

Waste Water Treatment

Water Well & Oil well

Salt industry

Coal

Mine

Custom well screens

Inform us of your specifications for the water well screen pipe, including diameter, slot opening size, length and percentage of open area. Based on that information, we can customized your products.

Technical Specs of Water Well Screen Pipe

| Diameter (mm) |

Wall Thickness (mm) |

Coupler Outside Diameter (mm) |

| 4 |

6 |

8 |

| Ø 127 |

√ |

|

|

Ø 127 |

| Ø 159 |

√ |

√ |

|

Ø 159 |

| Ø 168 |

√ |

√ |

|

Ø 168 |

| Ø 219 |

√ |

√ |

|

Ø 219 |

| Ø 273 |

√ |

√ |

|

Ø 273 |

| Ø 325 |

|

√ |

√ |

Ø 325 |

| Ø 426 |

|

√ |

√ |

Ø 426 |

| Ø 529 |

|

√ |

√ |

Ø 529 |

| Ø 630 |

|

√ |

√ |

Ø 630 |

|

Wall Thickness

(mm)

|

4 |

6 |

8 |

|

| Slot size(mm) |

1 |

1.5 |

2 |

3 |

1 |

1.5 |

2 |

3 |

1 |

1.5 |

2 |

3 |

|

| Percent Open Area (%) |

8.8 |

13.9 |

18.8 |

30.4 |

6.3 |

9.5 |

12.7 |

20 |

5.6 |

8.6 |

11.4 |

16.9 |

|

Wedge Wire Johnson Gtoundwater Screen Pipe, Dewatering Well Screen Tube Manufacturing Process

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Q7. What's the wire?

A: Profile wire: 2.5x4mm, Support Rod: 3.5mm

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!