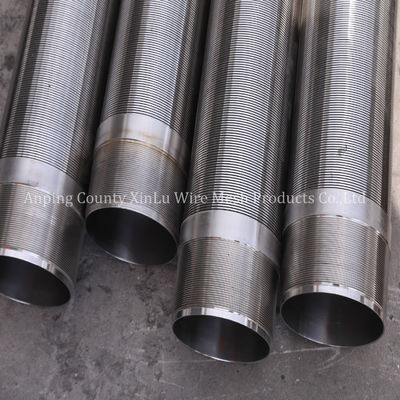

14" Water Well Screen Pipe

Product Description:

Features:

- Product Name: Water Well Screen Pipe

- Support rods: Φ2.5-6mm

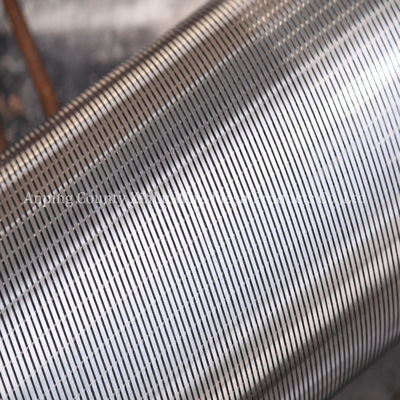

- Slot Size: 0.010", 0.020", 0.030", 0.040", 0.050", 0.060", 0.070", 0.080", 0.090", 0.10"

- Material: Stainless Steel304, 321, 316L, 205,201/Carbon Steel Q235,Q195/Duplex Steel 2205/Alloy Steel

- Support wire: 1.8x2.5mm, 2x3mm(Q25), 2.5x4mm, 3x5mm (Q35), 3x4.6mm, 3x6mm

- Size: 4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16"

Groundwater screen tube

Johnson screen pipe

Wire wrapped screen pipe

Technical Parameters:

| Type |

Size |

Thickness |

Weight |

Slot Size |

Wrapped Wire |

Surface Treatment |

Support Rods |

Collaspe Pressure (PSI) |

Pressure |

| Perforated |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

5mm To 12mm |

8-40kg/m2 |

N/A |

N/A |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

N/A |

300 |

Low/Medium/High |

| Wedge Wire Screen |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

5mm To 12mm |

8-40kg/m2 |

0.010", 0.020", 0.030", 0.040", 0.050", 0.060", 0.070", 0.080", 0.090", 0.10" |

0.75x1.8mm(11S), 1x2mm(12S), 1.5x2mm, 1.5x2.5mm(18S/#63), 2x3mm, 2.2x3.5mm(#93), 2.2x4.5(28SB)2.5x4mm, 3x4.6mm(#118), 3.3x6.2mm(#130) |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

Φ2.5-6mm |

300 |

Low/Medium/High |

| Johnson Screen Pipe |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

5mm To 12mm |

8-40kg/m2 |

N/A |

N/A |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

N/A |

300 |

Low/Medium/High |

| Slotted Liner |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

5mm To 12mm |

8-40kg/m2 |

0.010", 0.020", 0.030", 0.040", 0.050", 0.060", 0.070", 0.080", 0.090", 0.10" |

N/A |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

N/A |

300 |

Low/Medium/High |

| Wound Screen |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

5mm To 12mm |

8-40kg/m2 |

N/A |

0.75x1.8mm(11S), 1x2mm(12S), 1.5x2mm, 1.5x2.5mm(18S/#63), 2x3mm, 2.2x3.5mm(#93), 2.2x4.5(28SB)2.5x4mm, 3x4.6mm(#118), 3.3x6.2mm(#130) |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

N/A |

300 |

Low/Medium/High |

| Wire Wrapped |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

5mm To 12mm |

8-40kg/m2 |

N/A |

0.75x1.8mm(11S), 1x2mm(12S), 1.5x2mm, 1.5x2.5mm(18S/#63), 2x3mm, 2.2x3.5mm(#93), 2.2x4.5(28SB)2.5x4mm, 3x4.6mm(#118), 3.3x6.2mm(#130) |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

N/A |

300 |

Low/Medium/High |

Applications:

The Water Well Strainer Pipe comes in two models: 8-5/8" and 10-3/4". It is manufactured in Anping County Xinlu Wire Mesh Products Co.,Ltd. and has certifications such as FORM E, AFTA, and CO. The minimum order quantity for this product is 10pcs, with a price range of 30-120USD/m, depending on the specification.

The Water Well Screen Pipe is packaged using transparent plastic bags, woven bags, cartons, wooden boxes, and pallets. It has a delivery time of 7-10 days and payment terms of T/T. Xinlu Company has a supply ability of 500pcs per month.

The Water Well Screen Pipe fitting types include NPT, BSP, G, M, API, and STC. It has a pressure of 200 PSI, with thickness ranging from 5mm to 12mm. The weight of the Water Well Strainer Pipe ranges from 8-40kg/m2. The surface treatment options include electrolytic polishing, pickling, polished, sandblasting, and paint coating.

The Water Well Screen Pipe is a versatile product that can be used in various occasions and scenarios. It is ideal for use in water wells, boreholes, and water monitoring systems. It can also be used in municipal water supply systems, oil and gas exploration, and geothermal drilling. It is suitable for use in vertical, inclined, and horizontal wells.

The Water Well Screen Pipe is an essential tool in ensuring the efficient extraction of water and other liquids. It is a reliable and durable product that can withstand harsh conditions and environments. It is an investment that guarantees long-term benefits and value for money.

Customization:

Our Xinlu Company offers product customization services for our high-quality water well screen pipe, also known as wedge wire screen tube or Johnson well screen pipe.

The model numbers available for customization are 8-5/8" and 10-3/4". Our place of origin is Anping County Xinlu Wire Mesh Products Co.,Ltd and our products hold certifications including FORM E, AFTA, and CO.

The minimum order quantity for customization is 10pcs and the price ranges from 30-120USD/m depending on the specifications. We offer various packaging options including transparent plastic bags, woven bags, cartons, wooden boxes, and pallets.

Our delivery time is 7-10 days and we accept payment via T/T. With a supply ability of 500pcs/month, our water well screen pipe can withstand a pressure of 200 PSI.

We offer various support wire options including 1.8x2.5mm, 2x3mm(Q25), 2.5x4mm, 3x5mm (Q35), 3x4.6mm, and 3x6mm, and end connection options including Threaded NPT, BSP, NPS/Flange/Welded Rings/Plain/Plain Beveled Ends For Butt Welding.

Fitting types available for customization include NPT, BSP, G, M, API, and STC. Our water well screen pipes are made from high-quality materials including Stainless Steel304, 321, 316L, 205,201/Carbon Steel Q235,Q195/Duplex Steel 2205/Alloy Steel.

Support and Services:

Our Water Well Screen Pipe product is designed to provide superior performance and durability in a variety of applications. Our technical support and services include:

- Expert installation guidance

- Product training and education

- On-site troubleshooting and maintenance support

- Product customization to meet specific project needs

- Technical documentation and specifications

- Product performance testing and analysis

Our team of experienced professionals is dedicated to providing exceptional customer service and support at every stage of your project. Contact us today to learn more about our Water Well Screen Pipe product technical support and services.

Packing and Shipping:

Product Packaging:

- The Water Well Screen Pipe product is packaged in durable cartons.

- Each carton contains one piece of the screen pipe.

- The cartons are labeled with the product name, size, and quantity.

Shipping:

- The Water Well Screen Pipe product ships via standard ground shipping.

- Orders are typically processed and shipped within 1-2 business days.

- Shipping times may vary depending on the destination.

- Customers will receive a tracking number once the order has shipped.

- Please inspect the product upon delivery and contact us within 24 hours if there are any issues.

FAQ:

Q1: What is the brand name of the water well screen pipe?

A1: The brand name of the water well screen pipe is Xinlu Company.

Q2: What are the available model numbers for the water well screen pipe?

A2: The available model numbers for the water well screen pipe are 8-5/8" and 10-3/4".

Q3: Where is the water well screen pipe manufactured?

A3: The water well screen pipe is manufactured in Anping County Xinlu Wire Mesh Products Co.,Ltd.

Q4: What certifications does the water well screen pipe have?

A4: The water well screen pipe has FORM E, AFTA, and CO certifications.

Q5: What is the minimum order quantity for the water well screen pipe and what is the price?

A5: The minimum order quantity for the water well screen pipe is 10pcs and the price ranges from 30-120USD/m, according to the specification.

Q6: What are the packaging details and delivery time for the water well screen pipe?

A6: The packaging details for the water well screen pipe include transparent plastic bags, woven bags, cartons, wooden boxes, and pallets. The delivery time is 7-10 days.

Q7: What are the payment terms and supply ability for the water well screen pipe?

A7: The payment terms for the water well screen pipe are T/T and the supply ability is 500pcs/month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!