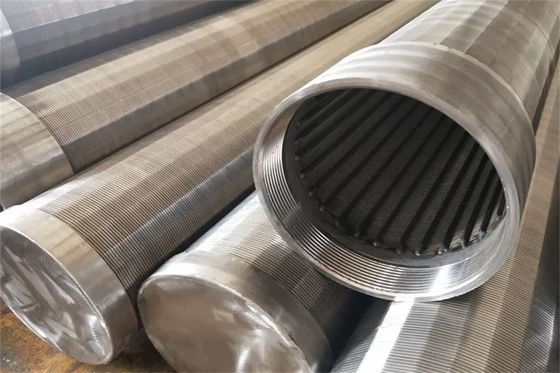

Electrolytic Polishing Threaded Wire Wrapped Screen Tube For Water Sand Control

Name: Johnson screen, Water wire screen, Water well screen, Wire warpped screen,Wedge wire screen, Johnson well screen, Johnson wire screen, Johnson screen tube, Johnson screen pipe, Johnson filter tube, Screen pipe, Screen tube, Dewatering well screen tube, stainless steel strainer pipe, oil well screen, changeable filter element, Motor Filter, Pump Filter, stainless steel filter candle, Header lateral Pipe, wedge wire strainer, perfect round screen tube, Slotted tube, Wound screen, Continuous slot screen fiter, Sand control screen,Wedge wire screen pipe, Rotary fiter drum, Oil screen. water wire screen,wound screen.

Electropolished Threaded Wire Wrapped Screen Tubes for Water and Sand Control

Product Introduction:

Anping County Xinlu Wire Mesh Products Co., Ltd is proud to present our Electrolytic Polishing Threaded Wire Wrapped Screen Tubes, designed for water sand control and filtration in various water well applications. These tubes are crafted from premium stainless steel materials and feature a threaded connection for secure installation.

Key Product Features:

- Material: Stainless Steel 205, 304, 316, 304L, 316L, 321, and other grades for corrosion resistance and strength.

- Outer Diameter (O.D.): Available in sizes from 3-1/2" to 12-3/4", customizable upon request.

- Slot Size: Ranging from 0.1mm to 1.5mm, with a standard discrepancy of +/- 0.05mm, to ensure precise filtration.

- Length: Customizable up to 6000mm, with standard lengths of 2950mm and 5850mm to fit shipping containers.

- End Connection: Options include Welded rings, Plain beveled ends, and Threaded couplings (API STC, PT NPT, BSP, G), as well as Flanges and Closed or Open ends.

- Flow Type: FOTI (External circumferential wire with axial internal support rods) and FITO (External circumferential inverted wire with axial internal support rods, or Internal axial wire with external circumferential support rods).

Advantages of Wire Wrapped Screens:

- Maximized Open Area: The design ensures the largest possible open area while maintaining structural integrity.

- Uniform Openings: The slots are uniformly arranged for direct water flow into the screen, enhancing filtration efficiency.

- Reachable Design: Allows for comprehensive formation development, ensuring effective water extraction.

V-Wire Wrapped Screen Pipe Wire Specification

|

SIZE

(INCH)

|

O.D

(MM)

|

SLOT

(MM)

|

LENGTH

(M)

|

COLLAPSE

STRENGTH

(BAR)

|

TENSILE

WEIGHT

(TON)

|

WRAP WIRE(WIDTH*HEIGHT)

(MM)

|

RODS

(MM)

|

| 3-1/2 |

88.9 |

1.0 |

3 |

>22 |

10.2 |

2.2x3.0 |

3.8MM/22 |

| 4-1/2 |

114.3 |

1.0 |

3 |

>28 |

11.5 |

2.3x3.5 |

3.8MM/22 |

| 6-5/8 |

168.3 |

0.75 |

5.8 |

>40 |

12.8 |

2.5x4.0 |

3.8MM/32 |

| 6-5/8 |

168.3 |

1.0 |

5.8 |

>33 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

0.63 |

5.8 |

>83 |

45 |

3.05x6.0 |

6.0MM/32 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>34 |

21.9 |

2.5x4.0 |

3.8MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>50 |

38.2 |

3.0x4.6 |

4.0MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>60 |

46 |

3.05x6.0 |

5.0MM/48 |

| 10-3/4 |

273.1 |

0.75 |

5.8 |

>50 |

32.9 |

2.5x4.0 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>60 |

39.5 |

3.0x4.6 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>100 |

48 |

3.05x6.0 |

5.0MM/55 |

| 12-3/4 |

323.9 |

1.0 |

5.8 |

>120 |

37.2 |

3.0x4.6 |

4.0MM/50 |

| 14 |

355.6 |

1.0 |

3 |

>80 |

37.8 |

3.0x4.6 |

4.0MM/59 |

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.00 |

1.50 |

1.50 |

2.00 |

2.30 |

2.50 |

3.00 |

3.05 |

| HEIGHT(mm) |

2.00 |

2.00 |

2.50 |

3.80 |

3.50 |

4.00 |

4.60 |

6.35 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

1.80 |

2.00 |

2.50 |

3.00 |

3.00 |

Ø2.5--Ø6mm |

| HEIGHT(mm) |

2.50 |

3.00 |

4.00 |

4.60 |

6.00 |

----

|

Applications:

Our wire wrapped screens are versatile and can be used in:

- Deep well pumps

- Water treatment equipment

- Environmental protection

- Seawater desalination

- Water softening

- Petroleum industry filtration

- Chemical and organic solution recycling

Customization and Quality Assurance:

We offer custom well screens tailored to your specifications, including diameter, slot opening size, length, and percentage of open area. Our commitment to quality includes:

- Dedicated Quality Control: Each production process is monitored by specialized personnel.

- Professional Engineering Review: Our engineers conduct thorough quality checks to ensure product excellence.

Frequently Asked Questions:

Q1: Can I have a sample order?

A: Yes, we welcome sample orders to test and check quality.

Q2: What about the lead time?

A: 3-5 days for sample preparation, 15-25 working days for mass production.

Q3: Do you have any MOQ limit for the order?

A: Low MOQ, with 3pcs available for sample checking.

Q4: How do you ship the goods and how long does it take to arrive?

A: We offer various shipping options, including express shipping which takes 5-7 days.

Q5: How to proceed an order?

A: Share your specifications, receive a quote, confirm and place a deposit, and we will arrange production.

Q6: Is it OK to print my logo on the product?

A: Yes, please inform us before production for logo printing.

About Anping County Xinlu Wire Mesh Products Co., Ltd:

As a leading manufacturer of wire mesh products, we are committed to delivering innovative and high-quality filtration solutions. Our focus on customer satisfaction and product excellence ensures that you receive the best products and services in the industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!