6 inch (152.40 mm) Inner Diameter Stainless Steel (SS)Wedge Wire Continuous Slot Strainer Pipe

wedge wire screens, v shaped wire welded stainless steel water well screens, low carbon galvanized water well screen, Johnson screen tube, johnson screen pipe, johnson well screen, johnson wire screen, johnson filter screen, johnson v wire screens,v wire slot tube, wire wrapped screen pipe, oil well screens, dewatering well screen, perfect roundness screen tube, profile wire screen pipe, reverse rolled screen tube, spiral screen tube, screen cylinders, rod based continous slot screens, sand conrol well screen, wire wound screen pipe, stainless steel filter elements, wedge wire roll screen, stainless steel strainer pipe,

Product Description:

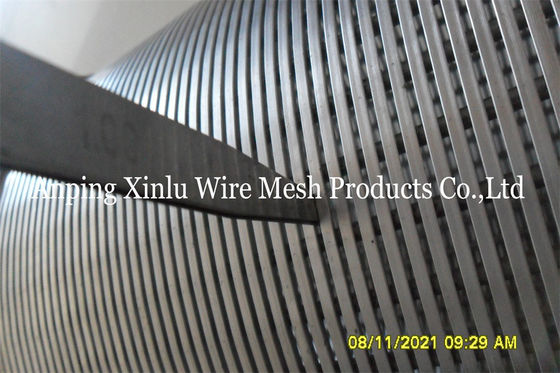

1. 6 inch (152.40 mm) Inner Diameter Stainless Steel (SS 304)Wedge Wire Strainer Pipe

2. fittings and male and female ( short) (STC)

3. thread API 8 threads per inch, taper 6.25%

4. In length of 5.80 meters

5. Axial Strength (M.T) ≥ 20.00

6. Axial Compression ≥12.00

7. External Hudrostatic Pressure (PSI) ≥80.00

8. V-wire - Openings 1.0 mm minimum

9. Dimensions of the wire: L = 2.7 mm, H = 3.5 mm minimum

10.Dimension of support rods: Diameter 3.0mm, Number 32pcs

Stainless Steel Wedge Wire Strainer Pipe Production Range:

1. Material: 316L, or according to customized, Stainless steel 304, Non-magnetic SS, Low carbon galvanized,Duplex steel etc.

2. Diameter: 25-2000mm (customized)

3. Slot: min 0.05mm

4. Length: 100-6000mm

5. Flow Type: FITO, FOTI

6. Ends:

Welded rings/Plain beveled ends;

Male/female threaded coupling: API STC, PT NPT, BSP, G;

Flange ;

Closed up,

Open ends etc.

7. Usage: Pump Filter, Motor Filter, Water Well,Waste Water Treatment,Water supply systems,Coal & Mine,Food Processors & Beverage Screens,Environmental protection,Refining & Petrochemical,Architecture & Construction etc.

Quality assurance: 6 inch (152.40 mm) Inner Diameter Stainless Steel (SS 304)Wedge Wire Strainer Pipe

- Every production process has a special person to test to ensure quality

- Have professional engineers to check the quality

Package: Stainless Steel Wedge Wire Strainer Pipe

Plastic bubble bag packaging

Transparent plastic bag inside, woven bag outside

Wooden box

Pallet

Stainless Steel Wedge Wire Strainer Pipe Specification

|

SIZE

(INCH)

|

O.D

(MM)

|

SLOT

(MM)

|

LENGTH

(M)

|

COLLAPSE

STRENGTH

(BAR)

|

TENSILE

WEIGHT

(TON)

|

WRAP WIRE

(WIDTH*HEIGHT)

(MM)

|

RODS

(MM)

|

| 3-1/2 |

88.9 |

1.0 |

3 |

>22 |

10.2 |

2.3x3.5 |

3.8MM/22 |

| 4-1/2 |

114.3 |

1.0 |

3 |

>28 |

11.5 |

2.3x3.5 |

3.8MM/22 |

| 6-5/8 |

168.3 |

0.75 |

5.8 |

>40 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

1.0 |

5.8 |

>33 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

0.63 |

5.8 |

>83 |

45 |

3.2x6.0 |

6.0MM/32 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>34 |

21.9 |

2.3x3.5 |

3.8MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>50 |

38.2 |

3.0x5.0 |

4.0MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>60 |

46 |

3.2x6.0 |

5.0MM/48 |

| 10-3/4 |

273.1 |

0.75 |

5.8 |

>50 |

32.9 |

2.3x3.5 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>60 |

39.5 |

3.0x5.0 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>100 |

48 |

3.2x6.0 |

5.0MM/55 |

| 12-3/4 |

323.9 |

1.0 |

5.8 |

>120 |

37.2 |

3.0x5.0 |

4.0MM/50 |

| 14 |

355.6 |

1.0 |

3 |

>80 |

37.8 |

3.0x5.0 |

4.0MM/59 |

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.00 |

1.50 |

1.50 |

2.00 |

2.30 |

2.50 |

3.00 |

3.05 |

| HEIGHT(mm) |

2.00 |

2.00 |

2.50 |

3.80 |

3.50 |

4.00 |

4.60 |

6.35 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

1.80 |

2.00 |

2.50 |

3.00 |

3.00 |

Ø2.5--Ø6mm |

| HEIGHT(mm) |

2.50 |

3.00 |

4.00 |

4.60 |

6.00 |

---- |

Stainless Steel Wedge Wire Strainer Pipe Application

water well

Juice

Beer

water supply systems

Refining & petrochemical

Filter equipment

Drum Filter

Sand control

Groundwater

Pump Filter

Motor Filter

Dewatering

Pharmaceutical

Groundwater

Architecture & Construction

Food & Beverage Screens

Mineral & Aggregate Processing

OEM Screen Components

Pulp & Paper Screens

Refining & Petrochemical

Waste Water Treatment

Water Well & Oil well

Salt industry

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!