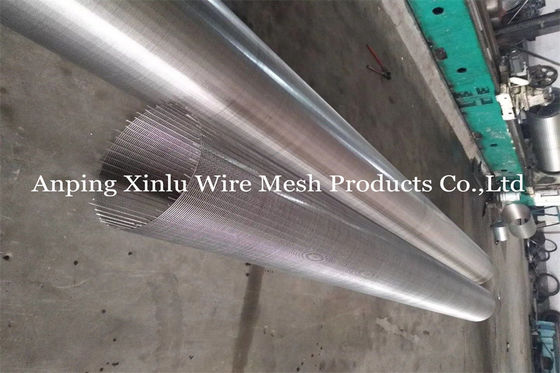

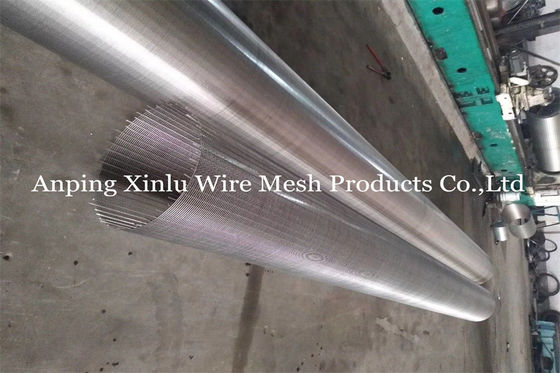

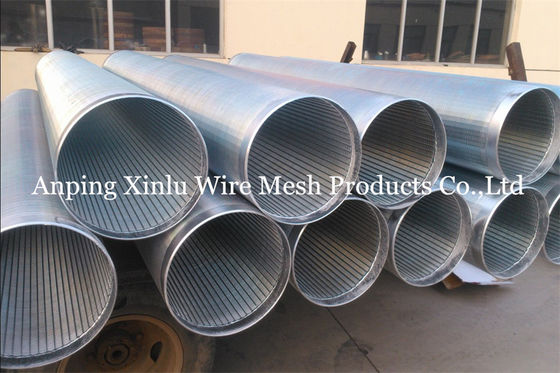

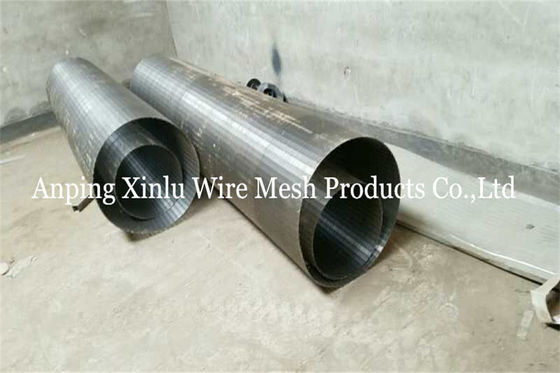

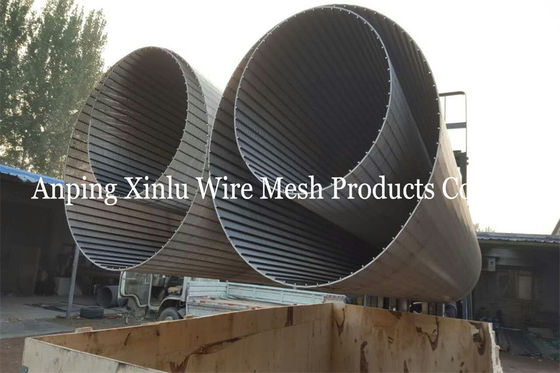

14" V Wire Wrap Johnson Water Well Sand Spiral Screen Tube For Heat Pump

wedge wire screens, v shaped wire welded stainless steel water well screens, low carbon galvanized water well screen, Johnson screen tube, johnson screen pipe, johnson well screen, johnson wire screen, johnson filter screen, johnson v wire screens,v wire slot tube, wire wrapped screen pipe, oil well screens, dewatering well screen, perfect roundness screen tube, profile wire screen pipe, reverse rolled screen tube, spiral screen tube, screen cylinders, rod based continous slot screens, sand conrol well screen, wire wound screen pipe, stainless steel filter elements, wedge wire roll screen, stainless steel strainer pipe,

Heat pumps are properly known as geothermal air conditioners. They transfer heat into or out of the ground to cool or heat your home by using a water well as a heat sink. The water well screen is a key component of geothermal wells, keeping sand out of the water pumping system

Features: V Wire Wrap Johnson Water Well Sand Spiral Screen Tube

1. Open Area Percentage

A high open area of more than 25% allows more water to flow easily with less flow resistance. The low entrance velocity reduces pressure drops, so less energy is needed for the pump.

2. Non-Clogging Slot

A vee-wire slot opening gets larger inwardly, reducing the chances of clogging. Less sand in the water flow also means less abrasion to the pump assembly, improving and extending the service life of the geothermal well.

3. High Pressure Resistance

Wedge wire is welded in a circular manner to support the rods as a single form, with no unappealing weld seams on the surface. A rigid welded construction also allows the pipes and screens to withstand a high water pressure.

4. Excellent Sand Control Performance

Precise slot control ensures an excellent filtration effect, reducing the risk of wear on the pump.

5. Easy Installation

As it is lighter than the bridge slot screen and cement pipes, Feiya-Xinlu's wedge wire well screen is easier and safer to install.

6. Materials

We use galvanized low carbon steel, and stainless steel. Quality materials do not retain impurities on the surface, providing a maximum flow rate.

Applications of V Wire Wrap Johnson Water Well Sand Spiral Screen Tube

This product is specifically designed for geothermal air conditioners for pumping water into and out of the ground.

Custom Solutions

Tell us your required specifications in regards to outside diameter, slot size, length and open area percentage, and we will produce wedge wire screens to fit those requirements and your needs.

Order Information V Wire Wrap Johnson Water Well Sand Spiral Screen Tube

Screen materials: stainless steel, galvanized carbon steel, carbon steel with plastic coating, or custom materials

Slot size: 0.1mm-15mm

Diameter (inches): 2,3,4,5,6,8,10,12,14,16,20. 29mm-1000mm

Length: 2.9m, 5.85m. The maximum length is 6.05m.

Connection method: beveled, circumferentially welded, or threaded connections

Main Specifications V Wire Wrap Johnson Water Well Sand Spiral Screen Tube

| Outside Diameter |

Inside Diameter |

Slot Size |

Percentage of Open Area |

Length |

| 117mm |

104mm |

0.25-2mm |

Above 11% |

Up to 6.05m |

| 168mm |

156mm |

0.5-2mm |

Above 14% |

Up to 6.05m |

| 219mm |

205mm |

0.5-2mm |

Above 14% |

Up to 6.05m |

| 273mm |

259mm |

0.5-2mm |

Above 14% |

Up to 6.05m |

| 325mm |

307mm |

0.5-2mm |

Above 14% |

Up to 6.05m |

| 377mm |

359mm |

1.0-2mm |

Above 25% |

Up to 6.05m |

| 426mm |

408mm |

1.0-2mm |

Above 25% |

Up to 6.05m |

NOTE: Data is the above tale are subject to change without notice.

V Wire Wrap Johnson Sand Screen Pipe Specification

|

SIZE

(INCH)

|

O.D

(MM)

|

SLOT

(MM)

|

LENGTH

(M)

|

COLLAPSE

STRENGTH

(BAR)

|

TENSILE

WEIGHT

(TON)

|

WRAP WIRE

(WIDTH*HEIGHT)

(MM)

|

RODS

(MM)

|

| 3-1/2 |

88.9 |

1.0 |

3 |

>22 |

10.2 |

2.3x3.5 |

3.8MM/22 |

| 4-1/2 |

114.3 |

1.0 |

3 |

>28 |

11.5 |

2.3x3.5 |

3.8MM/22 |

| 6-5/8 |

168.3 |

0.75 |

5.8 |

>40 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

1.0 |

5.8 |

>33 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

0.63 |

5.8 |

>83 |

45 |

3.2x6.0 |

6.0MM/32 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>34 |

21.9 |

2.3x3.5 |

3.8MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>50 |

38.2 |

3.0x5.0 |

4.0MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>60 |

46 |

3.2x6.0 |

5.0MM/48 |

| 10-3/4 |

273.1 |

0.75 |

5.8 |

>50 |

32.9 |

2.3x3.5 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>60 |

39.5 |

3.0x5.0 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>100 |

48 |

3.2x6.0 |

5.0MM/55 |

| 12-3/4 |

323.9 |

1.0 |

5.8 |

>120 |

37.2 |

3.0x5.0 |

4.0MM/50 |

| 14 |

355.6 |

1.0 |

3 |

>80 |

37.8 |

3.0x5.0 |

4.0MM/59 |

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.00 |

1.50 |

1.50 |

2.00 |

2.30 |

2.50 |

3.00 |

3.05 |

| HEIGHT(mm) |

2.00 |

2.00 |

2.50 |

3.80 |

3.50 |

4.00 |

4.60 |

6.35 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

1.80 |

2.00 |

2.50 |

3.00 |

3.00 |

Ø2.5--Ø6mm |

| HEIGHT(mm) |

2.50 |

3.00 |

4.00 |

4.60 |

6.00 |

---- |

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!