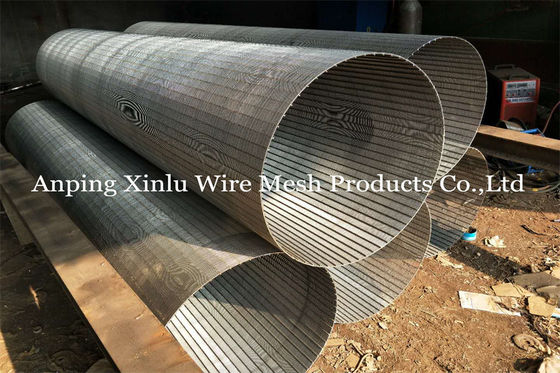

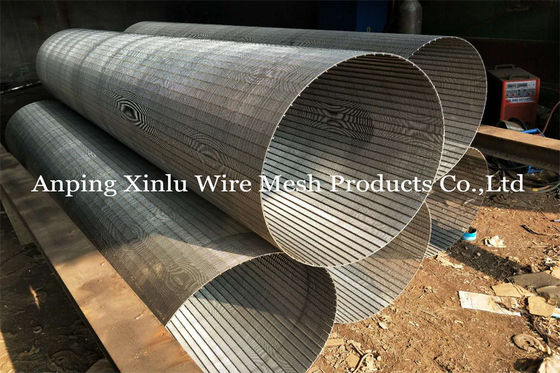

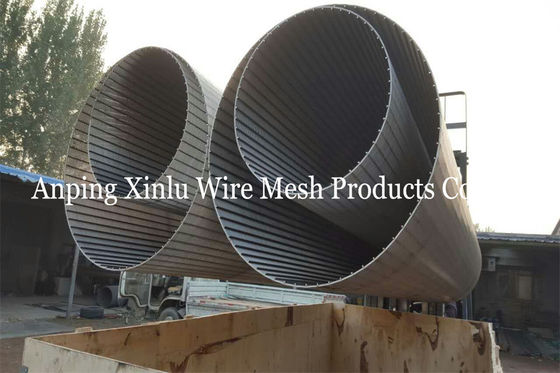

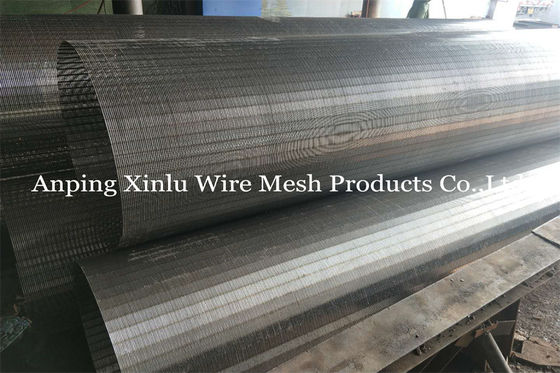

426mm Diameter Spiral Slot Water Well Screen Tube For GroundWater Filter Treatment

wedge wire screens, v shaped wire welded stainless steel water well screens, low carbon galvanized water well screen, Johnson screen tube, johnson screen pipe, johnson well screen, johnson wire screen, johnson filter screen, johnson v wire screens,v wire slot tube, wire wrapped screen pipe, oil well screens, dewatering well screen, perfect roundness screen tube, profile wire screen pipe, reverse rolled screen tube, spiral screen tube, screen cylinders, rod based continous slot screens, sand conrol well screen, wire wound screen pipe, stainless steel filter elements, wedge wire roll screen, stainless steel strainer pipe,

Spiral Slot Water Well Screen Tube Description:

Material: Stainless Steel wire (SS205B, 304, 316 ,etc) and Low Carbon Galvanized wire(LCG), Mild steel wire, Iron wire

Shape: Tube/pipe (Wire-wrapped stainless steel screen pipe, Water & Oil Well screen, Wedge wire screen, Changeable filter element, screen nozzle, Screen Cylinder, Spiral screen pipe, Strainer tube, Filter circumference, filter drum, v wire slot tube, screen basket. Cylinder screen,stainless steel lateral arm, hub lateral, head lateral,etc)

Plate/piece /Flat panel(Dewatering Screen Panel, Johnson Screen plate, v wire flat panel, wire wrappen panel, Sieve bend for coal, Arc screen plate, Vibrating screen plate, screen plate with Polyurethane frame, Curved screen, Wedge Wire Grating, )

Weaving: Full Welded

Used: Application in the water well, oil, mining, coal, oil, chemical fertilizers, food, environmental protection, sewage treatment, food filter screen mesh and other industries to sew, oil filter, wire net in salt industry,etc.

Spiral Slot Water Well Screen Tube Specifications

| Material |

Size

(Inch)

|

OD

(mm)

|

Slot

(mm)

|

Length

(m)

|

Collapse Strength

(PSI)

|

Tensile

Weight

(TON)

|

Profile wire

(WXH)

|

Support rod |

End Connection |

|

Q195

Q235

201

205

321

304

304L

316

316L

|

4 |

117 |

0.040 |

3-6 |

395 |

6 |

2.2*3.0 |

3.8MM/22 |

Threaded

Welded Rings

Flange

|

| 4 |

114.3 |

0.040 |

3-6 |

395 |

6 |

2.3*3.0 |

3.8MM/22 |

| 6 |

168.3 |

0.040 |

3-6 |

252 |

8 |

2.3*3.5 |

3.8MM/32 |

| 8 |

219.1 |

0.010 |

3-6 |

399 |

10.5 |

3.0*4.6 |

3.8MM/48 |

| 8 |

219.1 |

0.020 |

3-6 |

370 |

10.5 |

3.0*4.6 |

3.8MM/48 |

| 8 |

219.1 |

0.040 |

3-6 |

323 |

10.5 |

3.0*4.6 |

3.8MM/48 |

| 10 |

273.1 |

0.010 |

3-6 |

206 |

11 |

3.0*4.6 |

3.8MM/50 |

| 10 |

273.1 |

0.020 |

3-6 |

191 |

11 |

3.0*4.6 |

3.8MM/50 |

| 10 |

273.1 |

0.040 |

3-6 |

167 |

11 |

3.0*4.6 |

3.8MM/50 |

Spiral Slot Water Well Screen Tube Wire Size:

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.00 |

1.50 |

1.50 |

2.00 |

2.30 |

2.50 |

3.00 |

3.05 |

| HEIGHT(mm) |

2.00 |

2.00 |

2.50 |

3.80 |

3.50 |

4.00 |

4.60 |

6.35 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

1.80 |

2.00 |

2.50 |

3.00 |

3.00 |

Ø2.5--Ø6mm |

| HEIGHT(mm) |

2.50 |

3.00 |

4.00 |

4.60 |

6.00 |

---- |

Spiral Slot Water Well Screen Tube Advantage

1,A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2,A V shaped profile wire which avoids clogging and ensures an uninterrupted flow.

3,A uniform and efficient well development due to the continuous slot opening.

4,Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5,Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Spiral Slot Water Well Screen Tube Application: We provide screening solutions to almost every industry, including:

Architecture & Construction

Food & Beverage Screens

Mineral & Aggregate Processing

OEM Screen Components

Pulp & Paper Screens

Refining & Petrochemical

Waste Water Treatment

Water Well

Coal

Mine

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!