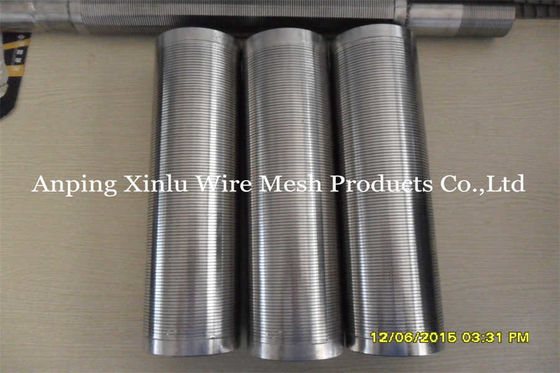

Ion Exchange Resin Trap Strainer Wedge Wire Candle Filter DN45

Category: Resin Traps

Material: stainless steel 304,304L,316,316L,321,430 or as per your request.

Properties: resin trap

Application: water-treatment, beer brewing, water well drilling, oil well drilling, mineral processing, coal-cleaning plant, refining & petrochemical

Product Details : Ion Exchange Resin Trap Strainer Wedge Wire Candle Filter DN45

Wedge Wire Candle Filter resin trap strainer used in water treatment processes namely in 'Ion Exchange' and other numerous media filter systems, our company offers a Resin Trap Screen. This screen system is primarily used as a safety device and is positioned immediately after the outlet nozzle of the vessel/reactor.

Wedge Wire Candle Filter resin trap strainers are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Feature of wedge wire candle filter resin trap strainer used for ion exchanger

-- High mechanical strength can bear large pressure drop

-- Equal slots for filtering can form equally distributed filter cake

-- The wedge type slot can improve backflushing and regeneration performance

-- It has resistant to pressure-temperature aging corrosion that can be applied for different kinds of fluid.

Application of wedge wire candle filter resin trap strainer used for ion exchanger

Mine Sieving Mesh Usage: Widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection, and other industries. For sieving liquid, powder, and other materials. In petroleum, chemical industry, metallurgy, mining, pharmaceutical purification, and drilling liquid purification.

Specifications of wedge wire candle filter resin trap strainer used for ion exchange:

| Material |

SS304, SS304L, SS316, SS316L, SS321, Duplex, Hastelloy, etc |

| OD Range |

25mm-2000mm |

| ID Range |

19mm-1981mm |

| Length Range |

Up to 6000 mm |

| Slot Range |

20 micron to 3000 microns (Tolerance:+-5 micron) |

| Wedge Wire |

0.5x1.5 |

0.75x1.5 |

1x2 |

1.5x2 |

2x3 |

2x4 |

| Support Rod |

1.5x2.5,2x3 |

1.5x2.5,2x3 |

1.5x2.5,2x3 |

1.8x2.5,2x3 |

3x5 |

3x5 |

| Connection |

Flange and thread |

| End Type |

Closed plate |

| Note |

Customized According To Special Requirement |

Our range of welded wedge wire candle filters are ideal for removing particles of very small size up to 10 microns. These filters can be easily washed through a back flush of the steam. We also provide options for different attachments to meet the specific process requirements of the clients.

welded wedge wire candle filters Specification

| No. |

Model Type |

N,D--mm

D

|

Branch Pipe Dia

d (Φmm)

|

Branch Pipe Number |

PN0.6/DN

Dimension of main pipe

|

| 1 |

FY-XL-125 |

1250 |

25-57 |

6-8 |

DN80 |

| 2 |

FY-XL-160 |

1600 |

28-57 |

6-8 |

DN80 |

| 3 |

FY-XL-180 |

1800 |

32-65 |

8-12 |

DN80-DN100 |

| 4 |

FY-XL-200 |

2000 |

42-89 |

8-12 |

DN80-DN125 |

| 5 |

FY-XL-220 |

2200 |

42-89 |

8-12 |

DN100-DN125 |

| 6 |

FY-XL-250 |

2500 |

57-89 |

8-16 |

DN100-DN125 |

| 7 |

FY-XL-280 |

2800 |

57-89 |

8-20 |

DN100-DN150 |

| 8 |

FY-XL-300 |

3000 |

57-89 |

8-20 |

DN125-DN200 |

| 9 |

FY-XL-320 |

3200 |

57-89 |

8-22 |

DN125-DN200 |

Note: Center distribution deainage device has many types: crossing type, fishbone type and straight type, etc

Material: 304,321,316,316L,904L ,HastalloyB and C, ets

Alll main pipes are adopted with flexible flange.

| Slot size |

Screen lateral diameter (mm) |

Vertical hub diameter (mm) |

Screen lateral flange diameter (mm) |

Vertical hub flange diameter (mm) |

Numbers of screen lateral |

0.05

0.1

0.2

0.3

0.5

1 |

32

40

57

76

89 |

76

89

108

133

159

219 |

25

32

40

50

65

80 |

50

65

80

100

125

150 |

6

8

10

12 |

welded wedge wire candle filters FEATURES:

- Backwashable welded wedge wire FOTI tubes

- Low heel volume

- Easy to clean smooth filtration surface

- Outside to inside flow

- No moving parts

- Permanent Filter element

- Fine Filtration down to particles (10 Microns and above)

ADVANTAGES: welded wedge wire candle filters

- Clean and hygienic operation

- Highest level safety for operator and process

- Eco-friendly operation

- Stand alone equipment

- Backwashing facility

- Permanent candles

- Steam back-washable

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!