Stainless Steel Od168mm 6-5/8"Wedge Wire Water Screen Pipe With 0.5mm Slot

wedge wire screens, v shaped wire welded stainless steel water well screens, low carbon galvanized water well screen, Johnson screen tube, johnson screen pipe, johnson well screen, johnson wire screen, johnson filter screen, johnson v wire screens,v wire slot tube, wire wrapped screen pipe, oil well screens, dewatering well screen, perfect roundness screen tube, profile wire screen pipe, reverse rolled screen tube, spiral screen tube, screen cylinders, rod based continous slot screens, sand conrol well screen, wire wound screen pipe, stainless steel filter elements, wedge wire roll screen, stainless steel strainer pipe

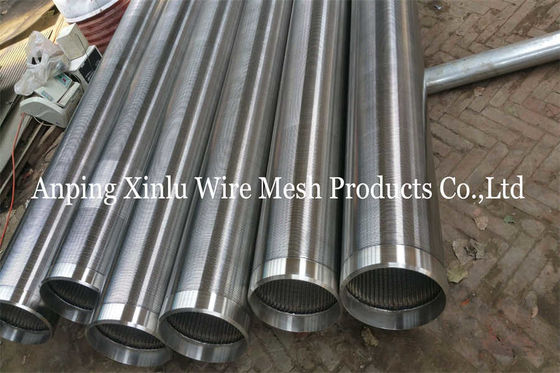

Stainless Steel O.D 168mm (6-5/8") Wedge Wire Screen Pipe With 0.5mm Slot

Wedge Wire Screen Pipe Description:

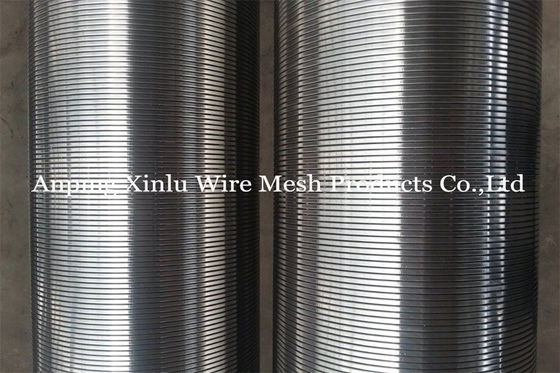

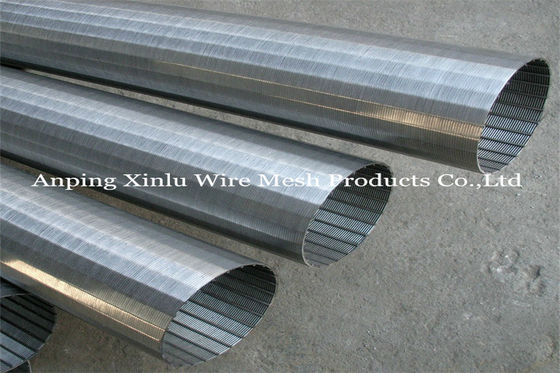

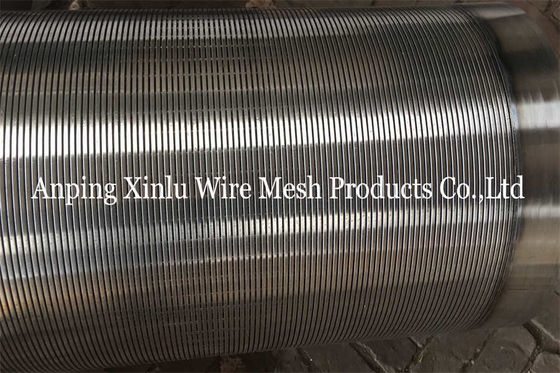

Wedge Wire Screen Pipe is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.There is a fixed value slot between each v wire, and the continuous slot, designed to provide maximum open are to reduce entrance velocity, increase hydraulic efficiency and promote more effective development.

Wedge Wire Screen Pipe Advantage:

Less Maintenance

The continuous slot design allows for lower entrance veloctiy of the water, reducing encrustation rates.

The slot design also resists plugging and prevents sand from damaging pumps.

Pumping Costs

The high open area of the Vee-Wire well screen allows for water to enter the well freely, resulting in minimal drawdown and less energy usage by a pump.

Optimal Performance Through

•Screens designed to site-specific yield requirements and aquifer characteristics

• Screen slot opening selected from formation sand sample analysis

• Wire and rod construction to deliver required strength for the specified well depth

• Stainless material selected to maximize corrosion resistance for water chemistry

• Wide variety of fittings to facilitate secure and efficient installation

Sand Control

The water well screen is a key component of the sand control system, either as an integral component of the gravel pack, or as a standalone provider of sand control. Patented Vee-Wire technology and welded construction, help to prevent well screen failure by better controlling the sand.

Johnson Wire Water Well Screen Pipe Range:

1. Material: 316L, or according to customized, Stainless steel 304, Non-magnetic SS, Low carbon galvanized,Duplex steel etc.

2. Diameter: 25-2000mm (customized)

3. Slot: min 0.05mm

4. Length: 100-6000mm

5. Flow Type: FITO, FOTI

6. Ends:

Welded rings/Plain beveled ends;

Male/female threaded coupling: API STC, PT NPT, BSP, G;

Flange ;

Closed up,

Open ends etc.

7. Usage: Pump Filter, Motor Filter, Water Well,Waste Water Treatment,Water supply systems,Coal & Mine,Food Processors & Beverage Screens,Environmental protection,Refining & Petrochemical,Architecture & Construction etc.

Quality assurance: Johnson Wire Water Well Screen Pipe

- Every production process has a special person to test to ensure quality

- Have professional engineers to check the quality

Package: Stainless Steel Wedge Wire Strainer Pipe

Plastic bubble bag packaging

Transparent plastic bag inside, woven bag outside

Wooden box

Pallet

Johnson Wire Water Well Screen Pipe Specification

|

SIZE

(INCH)

|

O.D

(MM)

|

SLOT

(MM)

|

LENGTH

(M)

|

COLLAPSE

STRENGTH

(BAR)

|

TENSILE

WEIGHT

(TON)

|

WRAP WIRE

(WIDTH*HEIGHT)

(MM)

|

RODS

(MM)

|

| 3-1/2 |

88.9 |

1.0 |

3 |

>22 |

10.2 |

2.3x3.5 |

3.8MM/22 |

| 4-1/2 |

114.3 |

1.0 |

3 |

>28 |

11.5 |

2.3x3.5 |

3.8MM/22 |

| 6-5/8 |

168.3 |

0.75 |

5.8 |

>40 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

1.0 |

5.8 |

>33 |

12.8 |

2.3x3.5 |

3.8MM/32 |

| 6-5/8 |

168.3 |

0.63 |

5.8 |

>83 |

45 |

3.2x6.0 |

6.0MM/32 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>34 |

21.9 |

2.3x3.5 |

3.8MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>50 |

38.2 |

3.0x5.0 |

4.0MM/48 |

| 8-5/8 |

219.1 |

1.0 |

5.8 |

>60 |

46 |

3.2x6.0 |

5.0MM/48 |

| 10-3/4 |

273.1 |

0.75 |

5.8 |

>50 |

32.9 |

2.3x3.5 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>60 |

39.5 |

3.0x5.0 |

4.9MM/55 |

| 10-3/4 |

273.1 |

1.0 |

5.8 |

>100 |

48 |

3.2x6.0 |

5.0MM/55 |

| 12-3/4 |

323.9 |

1.0 |

5.8 |

>120 |

37.2 |

3.0x5.0 |

4.0MM/50 |

| 14 |

355.6 |

1.0 |

3 |

>80 |

37.8 |

3.0x5.0 |

4.0MM/59 |

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.00 |

1.50 |

1.50 |

2.00 |

2.30 |

2.50 |

3.00 |

3.05 |

| HEIGHT(mm) |

2.00 |

2.00 |

2.50 |

3.80 |

3.50 |

4.00 |

4.60 |

6.35 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

1.80 |

2.00 |

2.50 |

3.00 |

3.00 |

Ø2.5--Ø6mm |

| HEIGHT(mm) |

2.50 |

3.00 |

4.00 |

4.60 |

6.00 |

---- |

Applications of Water Wire Screen ( substitute for Johnson deep well screen pipe)

Water Wire Screen: substitute for Johnson deep well screen pipe is used in the field of sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation; filtration of oils, greases, paints, food products, fuels, liquid cooling agents, chemicals etc.

OEM service:

We can produce products according to the needs of our customers.

Material: stainless steel 304, 316L, low carbon steel

Diameter: minimum diameter 32mm, maximum diameter 1270mm

Length: single tube can be up to 6 meters in length

Gap: 0.25mm, 0.5mm, 0.7mm, 1.0mm, 1.5mm is a regular gap. We can produce gaps of 0.1-50mm

Joints: Generally, there are joints at both ends of the pipe, such as flanges, weld rings, or threads, so that the pipes can be connected to meet the needs of use.

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Product Tags: od168mm wedge wire water screen pipe ; 0.5mm slot wedge wire water screen ; 6-5/8"wedge wire water screen pipe

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!