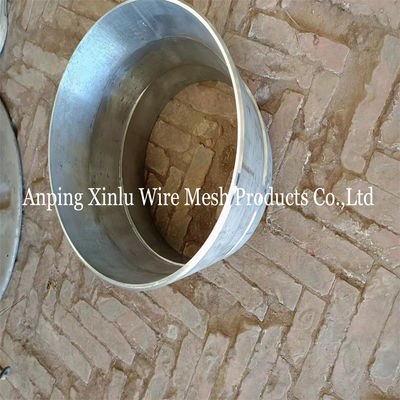

Diameter 426mm No magnetic Wire Wrapped Johnson Water Well Screen Pipe With Anti-Corrosion For Tube Well Filtration

Product Description:

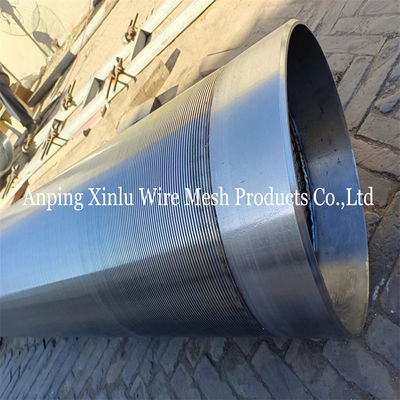

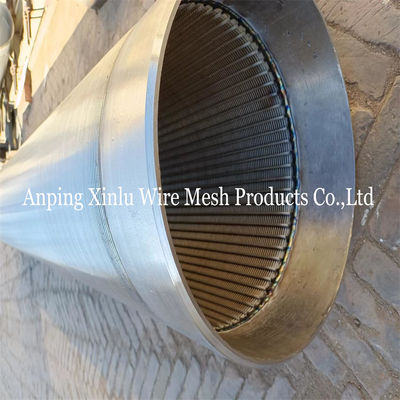

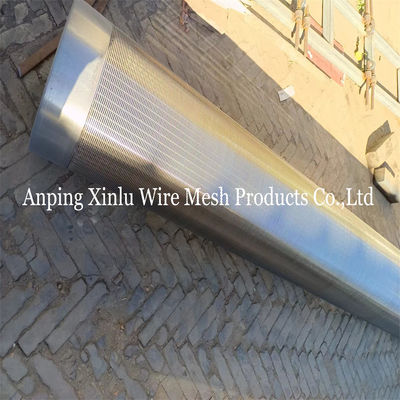

Water Well Screen Pipe is a kind of wedge wire screen pipe which is widely used for water well drilling, water treatment, oil and gas wells, natural gas industry and other industries. It is made of high quality stainless steel V-shape wire and support rod. This water well screen pipe is economical and suitable for most applications, with precision openings ranging from 12-400 mesh size. It also features various end connections including threaded NPT, BSP, NPS/Flange/Welded Rings/Plain/Plain Beveled Ends for Butt Welding, and it comes in a variety of sizes from 1 to 200 inches. Moreover, this water well screen pipe can handle pressure up to 200 PSI.

Features:

- Product Name: Water Well Screen Pipe

- Temperature: Low/Medium/High

- Thickness: 5mm To 12mm

- Length: 2.95m, 10ft, 5.85m, Up To 20foot Or Customized

- Type: Perforated/Wedge Wire/Johnson Screen/Slotted Liner/Wound Screen/Wire Wrapped

- Screen type: Standard Screen, Pipe-based Screen, Small Diameter Free-flow Well Screens.low Carbon Steel Well Screen,304 Stainless Steel Screen, Low Carbon Steel Galvanized Screens, Wire Wrapped Rod Base All Welded Screen

- Special Focus: stainless steel strainer tube, water well wound screens, wedge wire filter tube

Technical Parameters:

| Screen type |

Length |

| Standard Screen |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Pipe-based Screen |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Small Diameter Free-flow Well Screens |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Low Carbon Steel Well Screen |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| 304 Stainless Steel Screen |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Low Carbon Steel Galvanized Screens |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Wire Wrapped Rod Base All Welded Screen |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Groundwater Filtration Pipe |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Wire Wrapped Screen Tube |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| V Wire Slot Tube |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Stainless Steel Screen Pipe |

2.95m, 10ft, 5.85m, Up To 20foot Or Customized |

| Material |

Temperature |

Thickness |

Fitting type |

Slot Size |

Pressure |

Special features |

Pressure (PSI) |

| Stainless Steel304, 321, 316L, 205,201/Carbon Steel Q235,Q195/Duplex Steel 2205/Alloy Steel |

Low/Medium/High |

5mm To 12mm |

NPT, BSP, G, M, API, STC |

0.03mm To 10mm |

Low/Medium/High |

Reversed Construction: External Circumferential Inverted Wire And Axial Internal Support Rods (FITO), Normal Construction : External Circumferential Wire And Axial Internal Support Rods(FOTI) |

200 |

Applications:

Water Well Strainer Pipe manufactured by Xinlu Company, Anping County Xinlu Wire Mesh Products Co.,Ltd, is an ideal and reliable choice for filtering water, oil, gas, mining, motor, pump, sewage treatment, groundwater treatment, waste water treatment, water ion exchange, sand filter, activated carbon filter, sugar industry, paper industry and other applications. The strainer pipe is available in various sizes, such as 1", 2", 3", 4-1/2", 5", 6", 6-5/8", 7", 8", 8-5/8", 9-5/8", 10-3/4", 12-3/4", 14", 16" and other dimensions. It is made of stainless steel, v wire slot tube, Johnson type slot screen and other materials with high strength and corrosion resistance. The thickness of the water well strainer pipe can be 5mm to 12mm. The strainer pipe is certificated by FORM E, CO and can be customized according to customers' needs. It is available with NPT, BSP, G, M, API, STC fitting type. The minimum order quantity is 10pcs and the price is from 30 to 120USD/m, depending on the specifications. The package can be transparent plastic bags, woven bags, cartons, wooden boxes or pallets. The delivery time is 7-10days and the OEM service is available. The supply ability is up to 500pcs/month.

Customization:

Water Well Screen Pipe

- Brand Name: Xinlu Company

- Model Number: 1", 2", 3", 4-1/2", 5", 6", 6-5/8", 7", 8", 8-5/8", 9-5/8", 10-3/4", 12-3/4", 14", 16", etc

- Place of Origin: Anping County Xinlu Wire Mesh Products Co.,Ltd

- Certification: FORM E, CO

- Minimum Order Quantity: 10pcs

- Price: 30-120USD/m, according to the specification

- Packaging Details: Transparent plastic bags, woven bags, cartons, wooden boxes, pallets

- Delivery Time: 7-10days

- Payment Terms: T/T

- Supply Ability: 500pcs/month

- Collaspe pressure (PSI): 300

- Open area: Up To 60%

- OEM: Available

- Weight: 8-40kg/m2

- Slot Size: 0.03mm To 10mm

- Keywords: johnson screen pipe, water well wound screens, johnson well screen pipe

Support and Services:

We provide technical support and services for Water Well Screen Pipe, including:

- Installation and maintenance instructions.

- Troubleshooting assistance.

- Replacement parts.

- Warranty support.

- Dedicated customer service.

Packing and Shipping:

Packaging and Shipping for Water Well Screen Pipe

Water well screen pipes are packaged and shipped according to the standard export packaging. The pipes are loaded into containers, and the ends are covered with plastic film to prevent dust and water accumulation. The pipes are then secured in the containers with steel straps. The containers are labeled with the product information and are shipped to the destination.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!