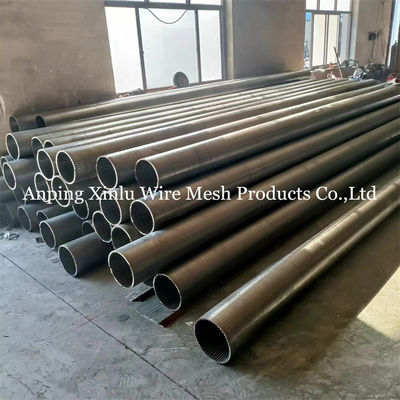

205 Water Well Screen Pipe with Slot Size 0.020" Wound Screen Wire Wrapped Slotted Liner

Product Description:

Available in different sizes, including 4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", and 16", our Water Well Screen Pipe can accommodate various well sizes. You can also choose from different end connection types, such as threaded NPT, BSP, NPS/flange/welded rings/plain/plain beveled ends for butt welding, to suit your specific requirements.

Our Water Well Screen Pipe is made from various materials, including stainless steel 304, 321, 316L, 205,201, carbon steel Q235, Q195, duplex steel 2205, and alloy steel. This allows us to provide you with a range of options that can withstand different environments and conditions.

Choose from different types of Water Well Screen Pipe, including perforated, wedge wire, Johnson screen, slotted liner, wound screen, and wire-wrapped. Each type has its unique features and benefits, allowing you to select what best suits your needs.

The Water Well Screen Pipe features support wires that come in different sizes, including 1.8x2.5mm, 2x3mm(Q25), 2.5x4mm, 3x5mm (Q35), 3x4.6mm, and 3x6mm. These support wires provide the necessary strength and structural integrity required for continuous slot screens.

Invest in our Water Well Screen Pipe for reliable and efficient filtering solutions. Whether you need to filter water for domestic or industrial purposes, our Water Well Screen Pipe can provide the best results. Trust us to deliver high-quality products that meet your specific requirements.

Features:

- Product Name: Water Well Screen Pipe

- Thickness: 5mm To 12mm

- Collaspe pressure (PSI): 300

- Pressure (PSI): 200

- Length: 2.95m, 10ft, 5.85m, Up To 20foot Or Customized

- Support wire: 1.8x2.5mm, 2x3mm(Q25), 2.5x4mm, 3x5mm (Q35), 3x4.6mm, 3x6mm

Also known as: Filter Johnson Strainer Pipe, johnson screen pipe, Groundwater screen tube

Technical Parameters:

| Attribute |

Value |

| Slot Size |

0.010", 0.020", 0.030", 0.040", 0.050", 0.060", 0.070", 0.080", 0.090", 0.10" |

| Pressure (PSI) |

200 |

| Pressure |

Low/Medium/High |

| Type |

Perforated/Wedge Wire/Johnson Screen/Slotted Liner/Wound Screen/Wire Wrapped |

| Size |

4-1/2", 6-5/8", 8-5/8", 10-3/4", 12-3/4", 14", 16" |

| Fitting type |

NPT, BSP, G, M, API, STC |

| Weight |

8-40kg/m2 |

| Support wire |

1.8x2.5mm, 2x3mm(Q25), 2.5x4mm, 3x5mm (Q35), 3x4.6mm, 3x6mm |

| Surface Treatment |

Electrolytic Polishing/ Pickling/Polished/Sand Blasting/Paint Coating |

| Collaspe pressure (PSI) |

300 |

This table shows technical parameters for the water well screen tube product, also known as v wire screen or wedge wire strainer pipe.

Applications:

These products are highly durable and can withstand a collapse pressure of up to 300 PSI. The weight of the water well screen tube ranges from 8-40kg/m2 depending on the specification. The water well screen tube can be customized to meet specific requirements and is available in different end connections including Threaded NPT, BSP, NPS/Flange/Welded Rings/Plain/Plain Beveled Ends for Butt Welding.

Xinlu Company's water well screen tubes are available in different types including perforated, wedge wire, Johnson screen, slotted liner, wound screen, and wire-wrapped. These types of water well screen pipes are used in different applications depending on the specific requirements. The Perforated water well screen pipe is commonly used in the oil and gas industry while the wedge wire and Johnson screen are used in water well drilling.

The slotted liner water well screen pipe is suitable for wells that require sand control and the wound screen water well screen pipe is perfect for deep wells. The wire-wrapped screen pipe is commonly used in the construction of municipal wells, industrial wells, and agricultural wells.

Xinlu Company's water well screen pipes are packed in transparent plastic bags, woven bags, cartons, wooden boxes, and pallets depending on the order. The minimum order quantity for these products is 10pcs and the delivery time is 7-10 days. The price of the water well screen pipe ranges from 30-120USD/m depending on the specification. Payments are made through T/T and the company has a supply capacity of 500pcs/month.

These water well screen pipes are made in Anping County Xinlu Wire Mesh Products Co., Ltd which is known for producing high-quality wire mesh products. Order your water well screen pipes from Xinlu Company today and enjoy high-quality products that will serve you for years.

Customization:

Looking for customized Filter Johnson Strainer Pipe? Look no further than Xinlu Company! Our water well screen tube comes in model numbers 8-5/8" and 10-3/4", and is made in Anping County Xinlu Wire Mesh Products Co.,Ltd. Our certification includes FORM E, AFTA, CO, and our minimum order quantity is 10pcs. Prices range from 30-120USD/m, depending on the specifications. Our packaging details include transparent plastic bags, woven bags, cartons, wooden boxes, and pallets. The delivery time for our johnson screen tube is 7-10 days, and we accept payment terms of T/T. Our supply ability is 500pcs/month.

Our water well screen pipe has a collaspe pressure (PSI) of 300, and wrapped wire options include 0.75x1.8mm(11S), 1x2mm(12S), 1.5x2mm, 1.5x2.5mm(18S/#63), 2x3mm, 2.2x3.5mm(#93), 2.2x4.5(28SB)2.5x4mm, 3x4.6mm(#118), 3.3x6.2mm(#130). End connection options include threaded NPT, BSP, NPS, flange, welded rings, plain, and plain beveled ends for butt welding. Our pressure (PSI) is 200, and the weight ranges from 8-40kg/m2.

Support and Services:

Our Water Well Screen Pipe product is backed by our exceptional technical support team and services. We offer:

- Expert advice and consultation regarding product selection and installation

- Customization options to meet specific project needs

- Product testing and analysis to ensure optimal performance and durability

- Repair and maintenance services to keep your system running smoothly

Our goal is to provide our customers with the highest level of support and service throughout the entire product lifecycle.

Packing and Shipping:

Product Packaging:

- The water well screen pipe is packaged in strong wooden crates to ensure safe transportation.

- The crates are securely strapped and wrapped to prevent any damage during transit.

Shipping:

- The water well screen pipe is shipped via sea or air freight depending on customer preference.

- We work with reliable shipping partners to ensure timely and safe delivery to our clients.

- Shipping costs are calculated based on the destination and weight of the order.

- Customers are provided with a tracking number to monitor the status of their shipment.

FAQ:

Q1: What is the brand name of the water well screen pipe?

A1: The brand name of the water well screen pipe is Xinlu Company.

Q2: What are the available model numbers for the water well screen pipe?

A2: The available model numbers for the water well screen pipe are 8-5/8" and 10-3/4".

Q3: Where is the water well screen pipe manufactured?

A3: The water well screen pipe is manufactured in Anping County Xinlu Wire Mesh Products Co.,Ltd.

Q4: What certifications does the water well screen pipe have?

A4: The water well screen pipe has certifications such as FORM E, AFTA, and CO.

Q5: What is the minimum order quantity for the water well screen pipe?

A5: The minimum order quantity for the water well screen pipe is 10pcs.

Q6: What is the price range of the water well screen pipe?

A6: The price range of the water well screen pipe is 30-120USD/m, according to the specification.

Q7: What are the packaging details for the water well screen pipe?

A7: The packaging details for the water well screen pipe include transparent plastic bags, woven bags, cartons, wooden boxes, and pallets.

Q8: What is the delivery time for the water well screen pipe?

A8: The delivery time for the water well screen pipe is 7-10 days.

Q9: What are the payment terms for the water well screen pipe?

A9: The payment terms for the water well screen pipe is T/T.

Q10: What is the supply ability for the water well screen pipe?

A10: The supply ability for the water well screen pipe is 500pcs/month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!