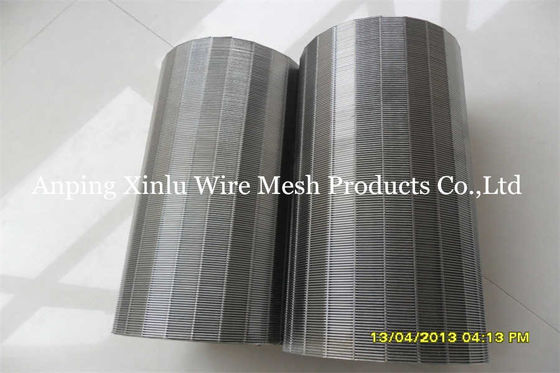

V Profile Wrapped Stainless Steel Reversed Wedge Wire Screen Pipe

stainless steel vee sharped wire / wrap wire, johnson screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainess steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod basedc ontinuous slot screens, header and hub laterals & hub radial laterals etc.

Wedge Wire wrap well Screen

Welded wedge wire screen is manufactured by flat welded screen in panel or cylinder type.

Flat welded wedge wire panels offer a perfectly flat and smooth surface with rectangular openings.

Welded Wedge Wire Screens are made from V shaped profile wire, with an unique welding process, offering great strength, precision, long service life and a wide range of applications in the field of process, engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

This kind of wedge wire can replace conventional media like wire mesh cloth, perforated plate and other metal sifting materials as components for rotary screen, well screen, quarry screen, etc..

Application:

Separating;

Sizing;

Straining;

De-watering;

Filtering;

Drying;

Water intake;

Media retention.

Cylindrical screen, changeable filter element, wedge wire cylinder element.

Inverted:

External circumferential inverted wire and axial internal support rods.

Benefits:

• economical

Applications:

• Inside-out flow

Internal circumFerential Wire (re-rolled)

internal circumferential wire with external axial support rods.

Benefits:

• Smooth internal filter surface

• custom inner diameter

Products:

• screw press

Internal axial wire (wire-base)

internal axial wire with external circumferential support rods.

Benefits:

• smooth internal screen surface

• Facilitates cleaning with an internal axial-movement scraper

• The flow moves across the wire edges for effective dewatering

Products:

• trommel screens with internal feed

• systems with an internal rotor or screw

• dewatering systems

• Baskets

• Automatic filters

Wedge Wire Water Screen Filter Pipe Uses

| |

|

| Specifications |

Wedge wire, slot size, support wire, support pitch sizes, screen thickness all can be customized as per your request. |

| Deep processed |

Wedge Wire Screen Panel

Wedge Wire Screen Pipe& Cylinder

Wedge Wire Screen Basket

Wedge Sieve Bend Screen

Wedge Wire lateral Screen pipe

Wedge Wire strainer nozzle

Wedge Wire rotary drum Screen

|

| Features |

1. High efficiency and high performance

2. Easy to move and install

3. Easy and convenient operation

4. Strong body

5. High corrosion resistant;

6. Long-use time;

7. Easy-cleaning;

8. Rust resistant;

9. Non-clogged

|

| Applications |

water supply systems

Refining & petrochemical

Filter equipment

Drum Filter

Sand control

Groundwater

Pump Filter

Motor Filter

Dewatering

Waste water-treatment

water well drilling

oil well drilling

mineral processing,

refining & petrochemical and other areas

|

| Slot Range |

30 micron to 3000 micron (Tolerance:+-5 micron) |

| Wedge Wire |

0.5x1.5 |

0.75x1.5 |

1x2 |

1.5x2 |

2x3 |

2x4 |

3x5 |

| Support Rod |

1.5x2.5

2x3

|

1.5x2.5

2x3

|

1.5x2.5

2x3

|

1.8x2.5

2x3

|

2x3

2x4

3x5

3x6

3x10

4x7

|

2x4

3x5

3x6

3x10

4x7

5x6

|

3x5

3x6

3x10

4x7

5x6

5x8

|

| End Finishing |

Thread fitting, Flange, Closed Plated, Resistance welded closed plate, Metal Ring, etc |

| Note |

Customized According To Requirement |

---------------------------------------------------------------------------------------------------------------

FAQ

Q: Are you trading company or manufacturer?

A: We are manufacturer.

Q:To quote,what’s information needed?

A: Material, slot (mesh size), diameter/ width, length, end type / frame size, quantity, usage,etc.

Q: How long is your delivery time?

A: It is 3-5 days if the goods are in stock; for mass order, it based on the quantity.

Q: Could you provide free sample?

A: Yes, it is available for free sample, but the customers need to pay the cost of freight, which can be deducted in following order.

Q: What is your terms of payment?

A: 30% T/T as deposit,the balance before shipment.

Q:How to confirm the quality about your products?

A:During production, a few samples can be delivered to you for quality confirmation. but the customers need to pay the cost of freight.

Q: How do you make our business long-term and good relationship?

A: Effective communication; Qualified products, competitive prices, timely delivery, considerate service, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!