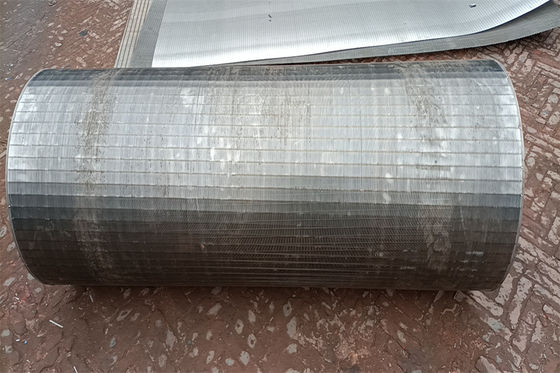

Strong Construction Angular Filter Screen Tube, Wedge Wire Strainer Pipe

Stainelss Steel Angular Filter Element / Wedge Wire Screen Pipr / Wedge Wire Cylindrical Strainer

Stainelss Steel Angular Filter Screen Introduction:

Minimum slot is 50um.

Wedge Wire Screen is produced through the method of electric resistance welding,

wires with profile profiles are welded to support rod at 90 degrees.

The distance between two profile wires is the slot opening, which is the filtration rate.

The structure is FOTI(flow-out-to-in) & FITO(flow-in-to-out).

Specification of Stainelss Steel Angular Filter Screen

Minimum slot: 0.05mm(50um)

Mimimum diameter: 16mm

Maxmum Length: 6000mm

Perfect roundness

Very smooth wire surface

Profile wire size: 0.75x1.5mm, 1.0x2.0mm, 1.5x2.5mm, 2.0x3.0mm, 2.0x4.0mm, 3.0x5.0mm...

Support Rod size: 2.0x3.0mm, 3.0x5.0mm, 5.0x8.0mm

Application of Stainelss Steel Angular Filter Screen

Coatings

Chemical

Petrochemical

Pulp and paper

Food and beverage

Solid-liquid separation

Waste water treatment

Mineral and aggregate processing

Advantages of Stainelss Steel Angular Filter Screen, wedge wire filter screen

High-precision slot opening: Minimum Slot opening is 50 microns.

Smooth Surface Filtration: very good smooth filtration surface, which reduce mechanical wear.

Non-clogging construction: The v-shaped wires and support rods is welded together by automatic resistance welding, which ensures a two- point contact between the particles and the slot,which minimizes clogging of near size product.

Strong construction: for most applications the wedge wire is self-supporting because of the welding at each intersection and can therefore withstand high pressure(Psi) and heavy loads.

| PROFILE WIRE |

|

|

|

|

|

|

|

|

| WIDTH(mm) |

1.00 |

1.50 |

1.50 |

2.00 |

2.30 |

2.50 |

3.00 |

3.05 |

| HEIGHT(mm) |

2.00 |

2.00 |

2.50 |

3.80 |

3.50 |

4.00 |

4.60 |

6.35 |

| SUPPORT ROD |

|

|

|

|

|

ROUND |

| WIDTH(mm) |

1.80 |

2.00 |

2.50 |

3.00 |

3.00 |

Ø2.5--Ø6mm |

| HEIGHT(mm) |

2.50 |

3.00 |

4.00 |

4.60 |

6.00 |

---- |

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing , 15-25 working days for mass production.

Q3. Do you have any MOQ limit for the order?

A: Low MOQ, 3pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Airline, sea shipping and rail transportation are all optional.

Or ship by EMS, DHL, UPS, FedEx or TNT, it takes 5-7 days to arrive.

Q5. How to proceed an order?

A: Firstly let us know your need specification or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!